Finest metal drill bits are an important device for any DIY fanatic or skilled. With the suitable drill bit, you’ll be able to sort out a variety of supplies, from wooden and plastic to metallic and concrete. On this article, we’ll discover the important thing traits of metal drill bits, how to decide on the suitable one in your wants, and the several types of metal drill bits obtainable.

We’ll additionally dive into the world of metal drill bit manufacturers, upkeep and care, widespread errors to keep away from, and the important instruments and equipment you may must get began together with your subsequent DIY mission.

What are the Finest Metal Drill Bits for Completely different Supplies?

Metal drill bits are an important device for any DIY fanatic or skilled contractor. Relating to choosing the proper drill bit for the job, materials choice performs an important function. Completely different supplies require distinctive traits in a drill bit, and choosing the proper one could make all of the distinction in reaching skilled outcomes. On this part, we are going to discover the traits of metal drill bits appropriate for drilling into numerous supplies similar to wooden, metallic, and plastic.

Drill Bits for Wooden

When drilling into wooden, it is important to make use of a drill bit that may successfully lower by means of the fabric with out inflicting injury or splintering. Wooden drill bits are designed with a pointy, leading edge and a sturdy building to resist the pains of drilling by means of several types of wooden. Some widespread options of wooden drill bits embody:

- Sharp leading edge for decreased splitting

- Sturdy building for elevated longevity

- Specialised suggestions for exact reducing

- Skill to drill by means of numerous kinds of wooden (e.g., hardwood, softwood)

Examples of wooden drill bits embody:

- High-quality-tooth drill bits for drilling by means of small, intricate areas

- Cream-tooth drill bits for drilling by means of bigger areas with excessive accuracy

- Auger drill bits for drilling giant holes or deep cavities

Drill Bits for Metallic

Drilling into metallic requires a drill bit that may face up to the excessive temperatures and stresses generated by reducing by means of the fabric. Metallic drill bits are designed with a specialised tip and a strong building to deal with these calls for. Some widespread options of metallic drill bits embody:

- Excessive-speed metal (HSS) or cobalt building for elevated sturdiness

- Specialised cooling techniques for decreased overheating

- Lowered vibration for extra correct drilling

- Skill to drill by means of numerous kinds of metallic (e.g., metal, aluminum, brass)

Examples of metallic drill bits embody:

- Excessive-speed metal (HSS) drill bits for drilling by means of metal and different ferrous metals

- Cobalt drill bits for drilling by means of non-ferrous metals like aluminum and brass

- Drill bits with built-in cooling techniques for high-speed drilling

Drill Bits for Plastic

Drilling into plastic requires a drill bit that may successfully lower by means of the fabric with out inflicting injury or melting. Plastic drill bits are designed with a pointy, leading edge and a light-weight building to reduce vibration and overheating. Some widespread options of plastic drill bits embody:

- Sharp leading edge for decreased put on and tear

- Light-weight building for decreased vibration

- Lowered friction for smoother drilling

- Skill to drill by means of numerous kinds of plastic (e.g., ABS, PVC, polycarbonate)

Examples of plastic drill bits embody:

- High-quality-tooth drill bits for drilling by means of small, intricate areas

- Coarse-tooth drill bits for drilling by means of thicker plastic supplies

- Drill bits with built-in anti-vibration techniques for decreased vibration

How one can Select the Proper Metal Drill Bit for Your Wants?

Relating to choosing the suitable metal drill bit in your particular wants, there are a number of elements to contemplate. The kind of materials you may be drilling into, the dimensions of the outlet, and the kind of metal drill bit you want are all essential in figuring out the very best drill bit for the job. On this part, we’ll break down the elements to contemplate and supply a complete information that can assist you make the suitable alternative.

Materials Concerns

The fabric of the metal drill bit is without doubt one of the most crucial elements to contemplate. Completely different supplies are appropriate for several types of drilling purposes. Listed here are among the most typical supplies utilized in metal drill bits:

- Cobalt Metal Drill Bits: These drill bits are made out of a high-speed metal alloy that incorporates cobalt. They are perfect for drilling by means of exhausting and abrasive supplies, similar to concrete, brick, and stone.

- Excessive-Pace Metal (HSS) Drill Bits: These drill bits are made out of a high-speed metal alloy that’s immune to put on and tear. They’re appropriate for drilling by means of a wide range of supplies, together with wooden, metallic, and plastic.

- Carbide-Tipped Drill Bits: These drill bits have a carbide-tipped shank that gives elevated sturdiness and longevity. They are perfect for drilling by means of exhausting supplies, similar to metal and brick.

- Fluted Drill Bits: These drill bits have a fluted design that enables for quicker drilling and decreased put on on the shank. They’re appropriate for drilling by means of a wide range of supplies, together with wooden, metallic, and plastic.

Measurement Concerns

The scale of the metal drill bit is one other crucial issue to contemplate. The scale of the drill bit will decide the dimensions of the outlet you may be drilling. Listed here are some widespread sizes of metal drill bits:

| Drill Bit Measurement | Materials | Description |

|---|---|---|

| 1/16 inch | Cobalt Metal | High-quality-grained, appropriate for drilling by means of wooden, metallic, and plastic. |

| 1/8 inch | HSS | Normal measurement, appropriate for drilling by means of a wide range of supplies. |

| 1/4 inch | Carbide-Tipped | Sturdy and long-lasting, appropriate for drilling by means of exhausting supplies. |

Sort Concerns

The kind of metal drill bit you want will depend upon the precise drilling utility. Listed here are among the most typical kinds of metal drill bits:

- Twist Drill Bits: These drill bits have a twisted design that enables for environment friendly drilling by means of a wide range of supplies.

- Spot Drill Bits: These drill bits have a small pilot gap that helps to stop the drill bit from slipping or wandering throughout drilling.

- Routing Drill Bits: These drill bits have a flute that enables for environment friendly removing of particles throughout drilling.

When choosing the proper metal drill bit in your wants, take into account the fabric, measurement, and sort of the drill bit. The suitable alternative will guarantee environment friendly and efficient drilling.

Varieties of Metal Drill Bits

Metal drill bits are available numerous varieties, every designed for particular duties and supplies. Choosing the proper sort of drill bit can vastly affect the success of your mission, whether or not you are knowledgeable contractor or a DIY fanatic. On this part, we’ll delve into the several types of metal drill bits, their designs, and purposes.

1. Twist Drill Bits

Twist drill bits are the most typical sort of drill bit. They include a cylindrical physique with a spiral flute, which removes the fabric as you drill. The twist drill bit is flexible and can be utilized for drilling numerous supplies, together with wooden, metallic, and plastic.

- Design: The twist drill bit has a pointy level and a spiral flute, which permits for environment friendly materials removing.

- Materials: Sometimes made out of high-speed metal (HSS) or tungsten carbide (TC), twist drill bits can be utilized for drilling numerous supplies.

- Purposes: Superb for general-purpose drilling, twist drill bits are good for drilling wooden, metallic, and plastic.

Twist drill bits are extensively obtainable and comparatively inexpensive. Nonetheless, they are often susceptible to put on and tear, particularly when drilling by means of exhausting supplies. To increase their lifespan, it is important to keep up correct drill bit sharpening strategies.

2. Screwdriver Bits

Screwdriver bits are designed for driving screws and bolts. They arrive in numerous styles and sizes, every fitted to particular screw head varieties. Screwdriver bits are sometimes made out of sturdy supplies, similar to HSS or TC, and are designed for heavy-duty use.

- Design: Screwdriver bits have a rounded or sq. tip, which inserts into the screw head.

- Materials: Sometimes made out of HSS or TC, screwdriver bits are designed for heavy-duty use.

- Purposes: Superb for driving screws and bolts, screwdriver bits are good for building, automotive, and industrial purposes.

Screwdriver bits are a must have for any DIY fanatic or skilled contractor. They arrive in numerous sizes and types, making it important to decide on the proper sort for the precise screw head.

3. Gap Noticed Bits

Gap noticed bits are designed for drilling giant holes in numerous supplies. They include a rotating noticed blade with a pilot drill bit on the middle. Gap noticed bits are good for drilling exact holes in wooden, metallic, and plastic.

- Design: The outlet noticed bit has a rotating noticed blade with a pilot drill bit on the middle.

- Materials: Sometimes made out of HSS or TC, gap noticed bits are designed for heavy-duty use.

- Purposes: Superb for drilling giant holes, gap noticed bits are good for woodworking, metalworking, and industrial purposes.

Gap noticed bits are a priceless addition to any toolkit. They’re designed for heavy-duty use and can be utilized for drilling exact holes in numerous supplies.

4. Step Drill Bits

Step drill bits are designed for drilling holes in numerous supplies, together with metallic and plastic. They include a number of stepped diameters, which permits for environment friendly drilling and decreasing the chance of breaking the drill bit.

- Design: The step drill bit has a number of stepped diameters, permitting for environment friendly drilling and decreased threat of breaking.

- Materials: Sometimes made out of HSS or TC, step drill bits are designed for heavy-duty use.

- Purposes: Superb for drilling holes in metallic and plastic, step drill bits are good for industrial and DIY purposes.

Step drill bits are a flexible addition to any toolkit. They’re designed for heavy-duty use and can be utilized for drilling exact holes in numerous supplies.

5. Masonry Drill Bits

Masonry drill bits are designed for drilling holes in concrete, brick, and different masonry supplies. They include a sturdy carbide tip and a spiral flute, which permits for environment friendly materials removing.

- Design: The masonry drill bit has a sturdy carbide tip and a spiral flute, permitting for environment friendly materials removing.

- Materials: Sometimes made out of carbide, masonry drill bits are designed for heavy-duty use.

- Purposes: Superb for drilling holes in concrete and brick, masonry drill bits are good for building and DIY purposes.

Masonry drill bits are a must have for any contractor or DIY fanatic working with masonry supplies. They’re designed for heavy-duty use and can be utilized for drilling exact holes in concrete and brick.

6. Metallic Drill Bits (e.g., Cobalt, Bi-Metallic)

Metallic drill bits are designed for drilling holes in numerous metallic supplies, together with metal and aluminum. They include a sturdy carbide tip and a spiral flute, which permits for environment friendly materials removing.

- Design: The metallic drill bit has a sturdy carbide tip and a spiral flute, permitting for environment friendly materials removing.

- Materials: Sometimes made out of carbide, metallic drill bits are designed for heavy-duty use.

- Purposes: Superb for drilling holes in metal and aluminum, metallic drill bits are good for building, automotive, and industrial purposes.

Metallic drill bits are a priceless addition to any toolkit. They’re designed for heavy-duty use and can be utilized for drilling exact holes in numerous metallic supplies.

7. Wooden Drill Bits (e.g., Forstner, Brad Level)

Wooden drill bits are designed for drilling holes in numerous wooden supplies, together with softwood and hardwood. They include a pointy level and a spiral flute, which permits for environment friendly materials removing.

- Design: The wooden drill bit has a pointy level and a spiral flute, permitting for environment friendly materials removing.

- Materials: Sometimes made out of HSS or TC, wooden drill bits are designed for heavy-duty use.

- Purposes: Superb for drilling holes in wooden, wooden drill bits are good for woodworking and DIY purposes.

Wooden drill bits are a must have for any woodworker or DIY fanatic. They’re designed for heavy-duty use and can be utilized for drilling exact holes in numerous wooden supplies.

8. Diamond-Coated Drill Bits

Diamond-coated drill bits are designed for drilling holes in numerous supplies, together with tile, stone, and concrete. They include a diamond-coated tip and a spiral flute, which permits for environment friendly materials removing.

- Design: The diamond-coated drill bit has a diamond-coated tip and a spiral flute, permitting for environment friendly materials removing.

- Materials: Sometimes made out of high-speed metal (HSS) or tungsten carbide (TC), diamond-coated drill bits are designed for heavy-duty use.

- Purposes: Superb for drilling holes in tile, stone, and concrete, diamond-coated drill bits are good for building and DIY purposes.

Diamond-coated drill bits are a priceless addition to any toolkit. They’re designed for heavy-duty use and can be utilized for drilling exact holes in numerous supplies.

9. Carbide-Tipped Drill Bits

Carbide-tipped drill bits are designed for drilling holes in numerous supplies, together with metallic and wooden. They include a carbide-tipped level and a spiral flute, which permits for environment friendly materials removing.

- Design: The carbide-tipped drill bit has a carbide-tipped level and a spiral flute, permitting for environment friendly materials removing.

- Materials: Sometimes made out of carbide, carbide-tipped drill bits are designed for heavy-duty use.

- Purposes: Superb for drilling holes in metallic and wooden, carbide-tipped drill bits are good for building, automotive, and DIY purposes.

Carbide-tipped drill bits are a must have for any contractor or DIY fanatic. They’re designed for heavy-duty use and can be utilized for drilling exact holes in numerous supplies.

10. Cobalt Drill Bits

Cobalt drill bits are designed for drilling holes in numerous supplies, together with metal and aluminum. They include a cobalt-tipped level and a spiral flute, which permits for environment friendly materials removing.

- Design: The cobalt drill bit has a cobalt-tipped level and a spiral flute, permitting for environment friendly materials removing.

- Materials: Sometimes made out of cobalt, cobalt drill bits are designed for heavy-duty use.

- Purposes: Superb for drilling holes in metal and aluminum, cobalt drill bits are good for building, automotive, and industrial purposes.

Cobalt drill bits are a priceless addition to any toolkit. They’re designed for heavy-duty use and can be utilized for drilling exact holes in numerous supplies.

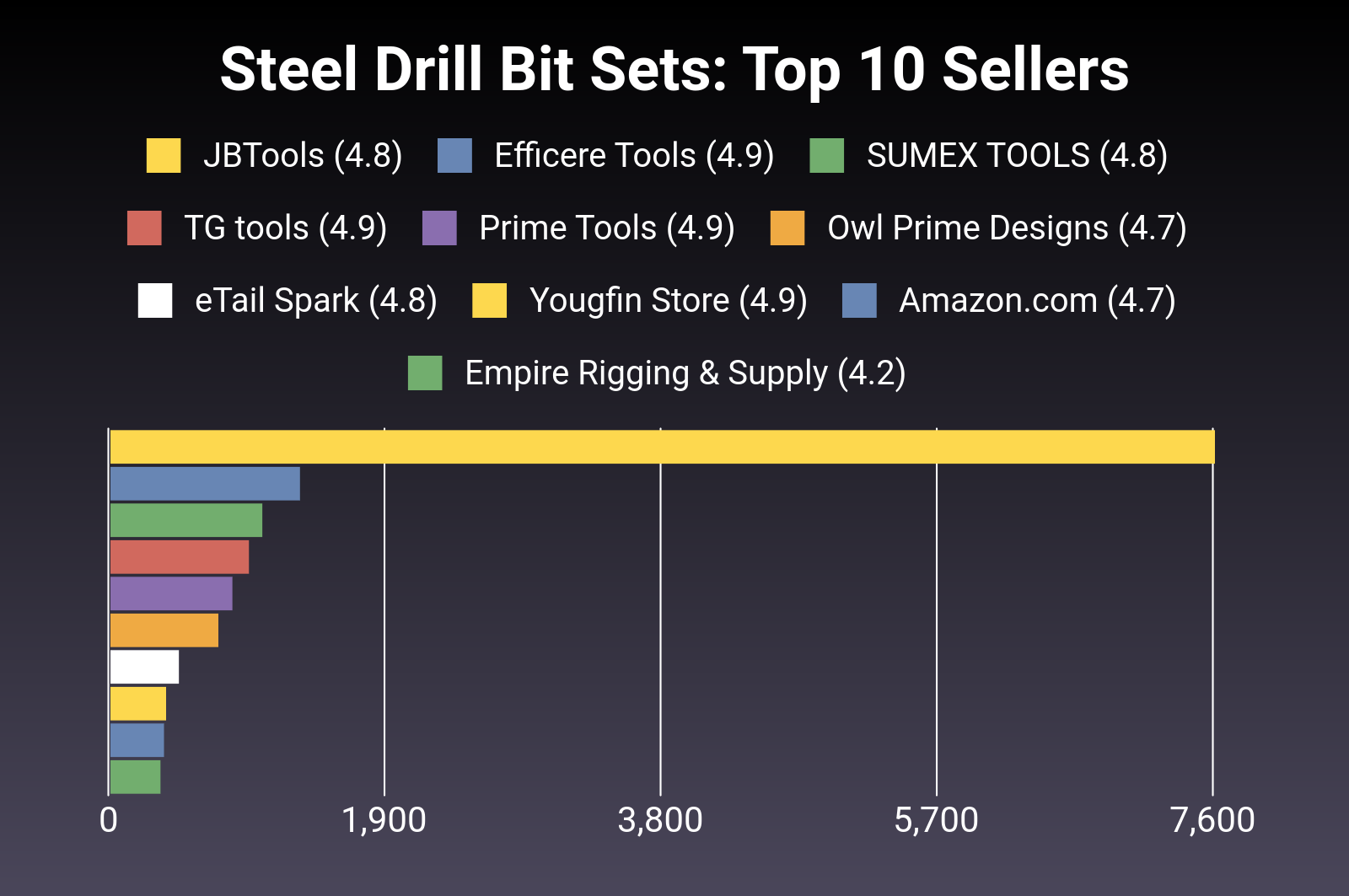

Finest Metal Drill Bit Manufacturers

Relating to metal drill bits, the suitable model could make a big distinction within the high quality and efficiency of your drilling mission. Every model has its distinctive options, advantages, and worth vary, making it important to decide on the very best one in your wants.

TopSteel Drill Bit Manufacturers

This is a comparability of the highest metal drill bit manufacturers available in the market:

| Model | Fame | High quality | Value Vary |

|---|---|---|---|

| DeWalt | Distinctive | Excessive | $20-$100 |

| Milwaukee | Glorious | Excessive | $25-$120 |

| Black+Decker | Good | Medium | $15-$60 |

| Skil | Common | Medium | $20-$80 |

| Stanley | Good | Excessive | $25-$100 |

Every model has its distinctive options and advantages, making it important to decide on the very best one in your particular wants.

Metal Drill Bit Upkeep and Care

Correct upkeep and care of metal drill bits are important to extend their lifespan and guarantee they proceed to carry out at their finest. Neglecting to correctly clear, retailer, and sharpen metal drill bits can result in decreased drilling effectivity, compromised accuracy, and in the end, the necessity for untimely alternative. By following these easy suggestions and tips, you’ll be able to hold your metal drill bits in high situation and preserve your drilling productiveness.

Cleansing Metal Drill Bits

Cleansing metal drill bits is an important step of their upkeep course of. Particles, metallic shavings, and different contaminants can accumulate on the bit’s leading edge, compromising its efficiency and lifespan. To wash your metal drill bits, comply with these steps:

- Use a smooth brush or a drill bit cleansing device to take away giant particles and metallic shavings from the leading edge.

- Soak the metal drill bit in a combination of water and a gentle detergent for a couple of minutes.

- Use a smooth material or a dry brush to wipe away any remaining particles and dry the bit.

- Rinse the bit with clear water and permit it to air dry.

It’s important to wash your metal drill bits after every use to stop the buildup of particles and preserve their accuracy and effectivity.

Storing Metal Drill Bits

Correct storage of metal drill bits is essential to stop injury, tangling, and corrosion. Listed here are some suggestions for storing your metal drill bits:

- Retailer metal drill bits in a dry, well-ventilated space, away from direct daylight and moisture.

- Use a drill bit storage case or a magnetic strip to prepare and defend your drill bits.

- Keep away from storing metal drill bits in a drawer or on a magnetic strip with different metallic objects, as this will trigger them to change into bent or broken.

- Retailer your metal drill bits of their unique packaging or in a chosen storage container to stop loss and injury.

By following these easy storage suggestions, you’ll be able to hold your metal drill bits in high situation and stop injury from improper storage.

Sharpening Metal Drill Bits

Sharpening metal drill bits is an important step in sustaining their accuracy and effectivity. A boring drill bit may cause injury to the fabric being drilled, resulting in decreased accuracy and elevated downtime. Listed here are some suggestions for sharpening your metal drill bits:

- Use a drill bit sharpener or a diamond stone to sharpen the reducing fringe of the metal drill bit.

- Begin with a rough grit and regularly transfer to finer grits to realize the specified stage of sharpness.

- Keep away from over-sharpening the metal drill bit, as this will compromise its energy and sturdiness.

- Use a drill bit sharpening device or a sharpening information to make sure correct and constant sharpening.

By following these easy sharpening suggestions, you’ll be able to preserve the accuracy and effectivity of your metal drill bits and guarantee they proceed to carry out at their finest.

Inspecting and Sustaining Metal Drill Bits

Common inspections and upkeep of your metal drill bits are important to make sure they proceed to carry out at their finest. Listed here are some suggestions for inspecting and sustaining your metal drill bits:

- Usually examine your metal drill bits for indicators of damage and tear, similar to chipping, cracking, or extreme put on on the leading edge.

- Use a drill bit inspection device or a magnifying glass to look at the leading edge and detect any indicators of injury.

- Use a drill bit restore package or a sharpening service to restore or sharpen broken drill bits.

- Keep away from utilizing broken or worn-out drill bits, as this will compromise accuracy and security.

By following these easy inspection and upkeep suggestions, you’ll be able to guarantee your metal drill bits proceed to carry out at their finest and preserve your drilling productiveness.

When working with metal drill bits, it is not unusual to come across widespread errors that may result in irritating experiences and wasted time. Nonetheless, by understanding the causes of those errors, you’ll be able to take steps to stop them and enhance the effectiveness of your drilling operations. On this part, we’ll talk about the most typical errors to keep away from when utilizing metal drill bits and supply tips about the best way to forestall and repair them.

Breakage

Breakage is without doubt one of the most typical errors when utilizing metal drill bits. This happens when the drill bit turns into broken, both attributable to extreme drive or poor bit high quality. Breakage can result in expensive repairs and delays in your mission. To forestall breakage, use the next strategies:

- Select a drill bit with a high-quality metal composition, similar to cobalt or high-speed metal, that are extra immune to put on and tear.

- Choose the suitable drill bit measurement for the job to keep away from making use of extreme drive.

- Apply regular, constant stress to the drill bit, relatively than making use of sudden bursts of drive.

- Usually examine your drill bits for indicators of damage and tear, and change them as wanted.

Slippage

Slippage happens when the drill bit loses its grip on the workpiece, leading to a poor or uneven gap. Slippage could be brought on by a wide range of elements, together with extreme pace, incorrect drill bit measurement, or poor workpiece materials. To forestall slippage, use the next strategies:

- Use a drill bit with a safe grip, similar to a twist drill or a self-centering drill.

- Choose the proper drill bit measurement for the job to keep away from making use of extreme stress.

- Apply sluggish, regular stress to the drill bit, relatively than making use of sudden bursts of drive.

- Use a lubricant or coolant to assist preserve a safe grip on the workpiece.

Uneven Holes

Uneven holes are a typical drawback when utilizing metal drill bits. This happens when the drill bit turns into boring or broken, inflicting the outlet to change into misaligned or irregular. To forestall uneven holes, use the next strategies:

- Usually examine your drill bits for indicators of damage and tear, and change them as wanted.

- Use a drill bit with a pointy, well-maintained leading edge to keep away from damaging the workpiece.

- Apply sluggish, regular stress to the drill bit, relatively than making use of sudden bursts of drive.

- Use a drill bit with a self-centering function, similar to a middle drill or a drill press, to assist preserve a straight and even gap.

Metal Drill Bit Set Necessities: Finest Metal Drill Bits

Relating to beginning a metal drill bit set, it is important to have the suitable instruments and equipment to make sure efficient drilling and storage. This consists of numerous kinds of drill bits, a storage case, and a charging station to maintain your bits organized and prepared to be used.

Should-Have Drill Bits

To get began, you may need to spend money on a wide range of important drill bits that may deal with completely different supplies and conditions. This may occasionally embody:

- Twist drill bits for general-purpose drilling

- Jobber drill bits for drilling deep holes

- Countersink drill bits for countersinking screws and different supplies

- Masonry drill bits for drilling by means of concrete and brick

- Faucet drill bits for making exact holes for tapping

These drill bits will present a strong basis in your metal drill bit set and assist you to sort out numerous tasks with confidence.

Storage Case and Group

A storage case and group system is essential for conserving your drill bits tidy and stopping injury. Search for a case that may maintain a number of drill bits, has particular person slots for every bit, and is made out of sturdy supplies.

Moreover, take into account investing in a charging station in your drill bits. This may assist you to hold your bits clear and charged, prolonging their lifespan and guaranteeing they’re at all times prepared to be used.

Different Important Instruments and Equipment

Whereas a drill bit set is the core of your metal drill, different important instruments and equipment can improve its efficiency and make it simpler to make use of. These could embody:

- Drill bit sharpeners for sustaining drill bit edge sharpness

- Drill bit storage pouches for carrying and defending particular person drill bits

- Drill bit organizers for conserving associated drill bits collectively

- Magnetic drill bit holders for handy bit storage and entry

By investing in these important instruments and equipment, you’ll get probably the most out of your metal drill bit set and sort out even probably the most difficult tasks with confidence.

Finest Metal Drill Bit for Particular DIY Tasks

Choosing the proper metal drill bit in your DIY mission is essential for reaching good outcomes, avoiding injury to the fabric being drilled, and lengthening the lifespan of the drill bit. On this part, we are going to talk about the very best metal drill bit for numerous DIY tasks, highlighting their distinctive options and advantages.

Drilling into Wooden

Relating to drilling into wooden, you may want a metal drill bit that may deal with the density and hardness of the wooden. For softwoods like pine or spruce, a 10-14mm cobalt-coated metal drill bit with a high-speed metal (HSS) tip is good. Such a drill bit gives wonderful reducing efficiency and minimizes the chance of the drill bit changing into caught or breaking.

Drilling into Metallic

For metalworking tasks, you may want a metal drill bit particularly designed for metallic drilling. A carbide-tipped metal drill bit is your best option, because it provides excellent reducing efficiency, sturdiness, and resistance to put on and tear. Such a drill bit additionally minimizes the chance of the drill bit changing into caught or breaking, even when drilling by means of exhausting metals like metal or aluminum.

Drilling into Concrete

Drilling into concrete requires a specialised metal drill bit designed particularly for masonry drilling. A tungsten carbide-coated metal drill bit with a HSS tip is the best choice, because it provides wonderful reducing efficiency and resistance to put on and tear. Such a drill bit is designed to deal with the excessive hardness and density of concrete, minimizing the chance of the drill bit changing into caught or breaking.

Drilling into Drywall, Finest metal drill bits

For drywall drilling, you may want a metal drill bit that may deal with the softness and brittleness of the fabric. A ten-14mm HSS metal drill bit with a high-carbon metal (HCS) tip is good, because it gives wonderful reducing efficiency and minimizes the chance of the drill bit changing into caught or breaking.

Drilling into Brick or Stone

Drilling into brick or stone requires a extremely specialised metal drill bit designed particularly for masonry drilling. A tungsten carbide-coated metal drill bit with an HSS tip is the best choice, because it provides wonderful reducing efficiency, sturdiness, and resistance to put on and tear. Such a drill bit is designed to deal with the excessive hardness and density of brick or stone, minimizing the chance of the drill bit changing into caught or breaking.

When choosing a metal drill bit in your DIY mission, at all times take into account the fabric being drilled and select a bit that’s particularly designed for that materials.

| Materials | Drill Bit Sort | Options |

|---|---|---|

| Wooden | 10-14mm cobalt-coated metal drill bit with HSS tip | Excessive-speed metal (HSS) tip, cobalt-coated for sturdiness |

| Metallic | Carbide-tipped metal drill bit | Carbide tip, wonderful reducing efficiency, excessive sturdiness |

| Concrete | Tungsten carbide-coated metal drill bit with HSS tip | Tungsten carbide-coated for enhanced reducing efficiency, HSS tip for sturdiness |

| Drywall | 10-14mm HSS metal drill bit with HCS tip | Excessive-carbon metal (HCS) tip, wonderful reducing efficiency, minimal threat of stickage |

| Brick or Stone | Tungsten carbide-coated metal drill bit with HSS tip | Tungsten carbide-coated for enhanced reducing efficiency, HSS tip for sturdiness |

Last Conclusion

In conclusion, choosing the proper metal drill bits in your wants is essential for reaching professional-grade outcomes. By understanding the several types of metal drill bits, their traits, and the best way to preserve and look after them, you’ll tackle any DIY mission with confidence. Bear in mind to at all times comply with security tips and use the proper drill bit for the job to make sure a clean and profitable mission.

Clarifying Questions

Q: What’s the finest metal drill bit for drilling into concrete?

A: For drilling into concrete, you may need to use a metal drill bit with a diamond-coated tip. Search for a bit with a high-speed metal (HSS) or cobalt metal building, as they’ll face up to the excessive temperatures generated when drilling into concrete.

Q: How do I forestall the drill bit from slipping out of the chuck?

A: To forestall the drill bit from slipping out of the chuck, make sure that to tighten the chuck securely earlier than beginning your mission. You too can use a drill bit key or a wrench to tighten the chuck additional if wanted.

Q: Can I take advantage of a metal drill bit to drill into metallic with no coolant?

A: No, it is not advisable to drill into metallic with no coolant. Drilling into metallic generates a whole lot of warmth, which may trigger the drill bit to overheat and break. Use a coolant, similar to water or a drilling lubricant, to maintain the drill bit cool and lengthen its lifespan.

Q: How usually ought to I sharpen a metal drill bit?

A: You need to sharpen a metal drill bit each 20-Half-hour of use, or whenever you discover the bit’s leading edge beginning to boring. Sharpening the bit repeatedly will assist preserve its efficiency and lengthen its lifespan.