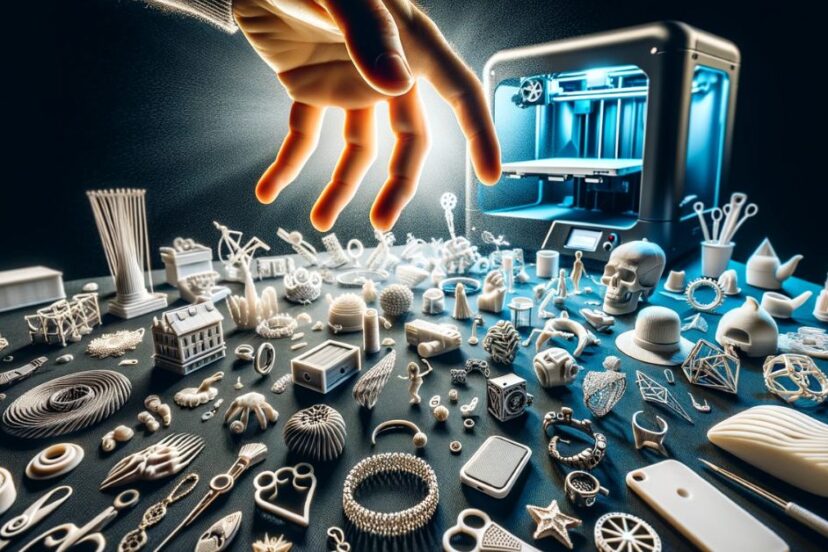

Delving into finest 3D printed gadgets, this introduction immerses readers in a novel and compelling narrative, offering a fascinating overview of the subject.

From purposeful gadgets resembling telephone instances and jewellery to ornamental gadgets like dwelling decor and toys, 3D printing know-how has revolutionized the way in which we create and work together with objects. With its countless prospects and customizability, the world of 3D printed gadgets is huge and thrilling.

Prime 10 Greatest 3D Printed Gadgets

In a world the place innovation meets creativity, 3D printing has emerged as a game-changer in numerous industries and houses. This know-how permits us to design and manufacture complicated objects with precision and velocity, opening doorways to countless prospects. From medical implants to ornamental artwork items, 3D printing has grow to be an integral a part of our lives.

The flexibility of 3D printing has led to the creation of a variety of things, every with its distinctive traits and functions. On this article, we are going to discover the highest 10 finest 3D printed gadgets which have revolutionized industries and houses alike.

Telephone Circumstances

Telephone instances made out of 3D printed supplies have grow to be a preferred pattern in recent times. Not solely do they supply safety to our units, however additionally they permit us to personalize our telephone’s appear and feel. With the power to create {custom} designs and patterns, 3D printed telephone instances have grow to be a favourite amongst telephone lovers. They’re additionally eco-friendly, as they are often made out of recycled supplies and bioplastics.

The method of making 3D printed telephone instances includes designing the case utilizing computer-aided design (CAD) software program, slicing the design into layers, after which printing the case utilizing a 3D printer. The result’s a sturdy and trendy telephone case that’s each purposeful and aesthetically pleasing.

- Customized designs and patterns

- Eco-friendly supplies

- Sturdy and long-lasting

- Simple to create and manufacture

Jewellery

3D printed jewellery has taken the style world by storm, providing a novel and customizable approach to create lovely items. From earrings to necklaces, 3D printed jewellery will be made out of a wide range of supplies, together with metals, plastics, and ceramics. The know-how permits for intricate designs and patterns, making every bit actually one-of-a-kind.

The method of making 3D printed jewellery includes designing the piece utilizing CAD software program, selecting the specified materials, after which printing the jewellery utilizing a 3D printer. The result’s a novel and attention-grabbing piece that’s each trendy and inexpensive.

- Customizable designs and patterns

- Intricate particulars and textures

- Big selection of supplies accessible

- Reasonably priced and accessible

Residence Decor

3D printed dwelling decor gadgets have grow to be more and more in style, providing a novel method so as to add a private contact to our residing areas. From ornamental objects to purposeful gadgets, 3D printing permits us to create a variety of dwelling decor items which might be each purposeful and aesthetically pleasing.

The method of making 3D printed dwelling decor gadgets includes designing the piece utilizing CAD software program, selecting the specified materials, after which printing the merchandise utilizing a 3D printer. The result’s a novel and trendy piece that provides a contact of character to our houses.

- Customizable designs and patterns

- Big selection of supplies accessible

- Intricate particulars and textures

- Reasonably priced and accessible

Medical Implants

3D printed medical implants have revolutionized the medical business, providing a brand new approach to create custom-made implants for sufferers. From hip alternative implants to dental implants, 3D printing permits for the creation of complicated designs and shapes which might be each exact and sturdy.

The method of making 3D printed medical implants includes designing the implant utilizing CAD software program, selecting the specified materials, after which printing the implant utilizing a 3D printer. The result’s a exact and sturdy implant that meets the precise wants of every affected person.

- Customized-made designs and shapes

- Exact and correct

- Sturdy and long-lasting

- Elevated affected person satisfaction

Toys

3D printed toys have grow to be more and more in style, providing a novel and enjoyable method for youngsters to study and play. From dolls to puzzles, 3D printing permits for the creation of a variety of toys which might be each instructional and entertaining.

The method of making 3D printed toys includes designing the toy utilizing CAD software program, selecting the specified materials, after which printing the toy utilizing a 3D printer. The result’s a novel and interesting toy that’s each enjoyable and academic.

- Customizable designs and patterns

- Intricate particulars and textures

- Big selection of supplies accessible

- Reasonably priced and accessible

Prosthetics

3D printed prosthetics have revolutionized the lives of amputees, providing a brand new approach to create custom-made prosthetic limbs. From arms to ft, 3D printing permits for the creation of complicated designs and shapes which might be each exact and sturdy.

The method of making 3D printed prosthetics includes designing the prosthetic utilizing CAD software program, selecting the specified materials, after which printing the prosthetic utilizing a 3D printer. The result’s a exact and sturdy prosthetic that meets the precise wants of every affected person.

- Customized-made designs and shapes

- Exact and correct

- Sturdy and long-lasting

- Elevated affected person satisfaction

Customized Elements

3D printed {custom} components have grow to be more and more in style, providing a novel approach to create complicated and custom-made components for machines and gear. From automotive components to aerospace parts, 3D printing permits for the creation of exact and sturdy components which might be each purposeful and aesthetically pleasing.

The method of making 3D printed {custom} components includes designing the half utilizing CAD software program, selecting the specified materials, after which printing the half utilizing a 3D printer. The result’s a exact and sturdy half that meets the precise wants of every machine or gear.

- Customized-made designs and shapes

- Exact and correct

- Sturdy and long-lasting

- Elevated effectivity and productiveness

Inventive Masterpieces

3D printed inventive masterpieces have taken the artwork world by storm, providing a brand new approach to create complicated and complex designs. From sculptures to jewellery, 3D printing permits for the creation of distinctive and breathtaking items which might be each aesthetically pleasing and sturdy.

The method of making 3D printed inventive masterpieces includes designing the piece utilizing CAD software program, selecting the specified materials, after which printing the piece utilizing a 3D printer. The result’s a novel and gorgeous piece that’s each lovely and sturdy.

- Customizable designs and patterns

- Intricate particulars and textures

- Big selection of supplies accessible

- Reasonably priced and accessible

Useful Gadgets

3D printed purposeful gadgets have grow to be more and more in style, providing a novel approach to create on a regular basis gadgets. From kitchen utensils to home goods, 3D printing permits for the creation of exact and sturdy gadgets which might be each purposeful and aesthetically pleasing.

The method of making 3D printed purposeful gadgets includes designing the merchandise utilizing CAD software program, selecting the specified materials, after which printing the merchandise utilizing a 3D printer. The result’s a exact and sturdy merchandise that meets the precise wants of every family.

- Customizable designs and patterns

- Intricate particulars and textures

- Big selection of supplies accessible

- Reasonably priced and accessible

Structure Fashions

3D printed structure fashions have revolutionized the way in which architects and engineers design and construct buildings. From buildings to bridges, 3D printing permits for the creation of exact and correct fashions which might be each purposeful and aesthetically pleasing.

The method of making 3D printed structure fashions includes designing the mannequin utilizing CAD software program, selecting the specified materials, after which printing the mannequin utilizing a 3D printer. The result’s a exact and correct mannequin that meets the precise wants of every undertaking.

- Customizable designs and patterns

- Intricate particulars and textures

- Big selection of supplies accessible

- Reasonably priced and accessible

Advantages of 3D Printed Gadgets

Within the realm of contemporary manufacturing, 3D printing has emerged as a game-changer, providing a plethora of advantages that span throughout numerous industries and functions. With its distinctive skill to create complicated shapes and buildings with ease, 3D printing has revolutionized the way in which we design, prototype, and produce items.

This revolutionary know-how has not solely remodeled the way in which we create objects however has additionally provided a mess of benefits which have far-reaching impacts on our surroundings, financial system, and society. On this section, we delve into the advantages of 3D printed gadgets, exploring their cost-effectiveness, customization capabilities, and sustainability.

Price-Effectiveness

One of the important benefits of 3D printing is its cost-effectiveness. By eliminating the necessity for conventional tooling and molds, 3D printing reduces the upfront prices related to product growth. Moreover, 3D printing permits for the creation of complicated shapes and buildings that might be costly or not possible to provide utilizing conventional manufacturing strategies.

- Diminished materials waste: 3D printing minimizes materials waste by printing solely the required quantity of fabric required for the thing.

- Quicker manufacturing: 3D printing permits speedy prototyping and manufacturing, considerably decreasing the time-to-market for brand new merchandise.

- No tooling prices: 3D printing eliminates the necessity for conventional tooling and molds, decreasing upfront prices and permitting for extra flexibility in design.

Customization

One other important good thing about 3D printing is its skill to supply customization. With the power to create complicated shapes and buildings, 3D printing permits the creation of tailor-made merchandise that meet particular buyer wants. Whether or not it is a custom-made prosthetic limb or a customized telephone case, 3D printing presents unparalleled flexibility in design and manufacturing.

- Customized merchandise: 3D printing permits the creation of custom-made merchandise that meet particular buyer wants, providing a novel and personalised expertise.

- Advanced geometries: 3D printing permits for the creation of complicated shapes and buildings that might be tough or not possible to provide utilizing conventional manufacturing strategies.

- Design flexibility: 3D printing presents designers the liberty to experiment with progressive and sophisticated designs, pushing the boundaries of what’s doable.

Sustainability

Along with its cost-effectiveness and customization capabilities, 3D printing additionally presents a extra sustainable different to conventional manufacturing strategies. By decreasing materials waste and power consumption, 3D printing minimizes its environmental impression.

| Environmental Impression | 3D Printing Comparability |

|---|---|

| Materials waste | Diminished by as much as 90% |

| Vitality consumption | Diminished by as much as 90% |

| Greenhouse gasoline emissions | Diminished by as much as 80% |

In line with a research by the Harvard Enterprise Evaluate, 3D printing can cut back power consumption by as much as 90% and materials waste by as much as 90% in comparison with conventional manufacturing strategies.

Sorts of Supplies Utilized in 3D Printing

Within the realm of 3D printing, the flexibility of supplies performs a pivotal function in crafting a big selection of progressive merchandise. The choice of supplies depends upon the meant utility, desired properties, and the extent of complexity required. The various forms of supplies utilized in 3D printing are as follows:

Plastics are the commonest and versatile group of supplies utilized in 3D printing. They embody:

- Polylactic Acid (PLA): A biodegradable thermoplastic derived from corn starch or sugarcane.

- Acrylonitrile Butadiene Styrene (ABS): A powerful and impact-resistant thermoplastic generally utilized in 3D printing.

- Polypropylene (PP): A versatile and sturdy thermoplastic.

Metals maintain quite a few benefits over conventional supplies, together with power, sturdiness, and conductivity. A few of the major metals utilized in 3D printing are:

- Copper: Identified for its excessive thermal conductivity and electrical conductivity.

- Titanium: Utilized in aerospace and industrial functions resulting from its excessive strength-to-weight ratio.

- Stainless Metal: Offers wonderful corrosion resistance and excessive sturdiness.

Ceramics are used to create merchandise with excessive thermal resistance, chemical resistance, and sturdiness. Some examples of ceramics embody:

- Alumina Ceramic: Reveals wonderful thermal conductivity and resistance to corrosion.

- Silicon Carbide (SiC): Affords excessive power, thermal resistance, and chemical resistance.

Glass is a well-liked alternative for 3D printing resulting from its wonderful sturdiness, transparency, and chemical resistance. Some notable examples of 3D-printed glass supplies embody:

- Extremely-dense glass: Reveals excessive density, making it appropriate for functions requiring low porosity.

- Clear glass: Used for creating intricate and clear parts.

The choice of supplies in 3D printing depends upon the required properties and utility of the ultimate product. The various vary of supplies permits creators to design and fabricate progressive merchandise with distinctive traits, increasing the chances of this know-how.

Purposes of 3D Printed Gadgets in Varied Industries

The realm of 3D printing has transcended the confines of a mere prototyping software, seamlessly embracing an array of industries the place precision, sturdiness, and innovation are paramount. From the cosmos to the confines of our houses, 3D printing has infiltrated numerous sectors, providing distinctive options, and propelling industries in direction of unparalleled ranges of progress.

Aerospace Business: Pioneering New Frontiers

The aerospace business has been on the forefront of embracing 3D printing know-how, using it to create complicated parts that might be not possible to provide utilizing conventional strategies. 3D printed components within the aerospace business have improved:

– Structural Integrity: Light-weight but sturdy parts that cut back gas consumption and improve general flight effectivity.

– Customization: Advanced geometries and designs that might be difficult to provide utilizing conventional manufacturing strategies.

– Materials Effectivity: Diminished materials utilization, resulting in important weight financial savings and decrease manufacturing prices.

The usage of 3D printing within the aerospace business has elevated by 25% yearly, with the purpose of manufacturing 40% of plane parts by 2025.

Medical Business: Revolutionizing Healthcare

The medical business has witnessed a major transformation with the appearance of 3D printing, because it permits the creation of custom-made prosthetics, implants, and anatomical fashions that considerably enhance:

– Personalization: Custom-made prosthetics and implants tailor-made to particular person sufferers’ wants, enhancing their high quality of life.

– Surgical Planning: Exact anatomical fashions that support surgeons in planning complicated procedures, decreasing operation instances and enhancing outcomes.

– Coaching: Sensible fashions for medical college students and professionals to apply and hone their expertise.

Automotive Business: Shifting in direction of Sustainability

The automotive business has harnessed the facility of 3D printing to create progressive parts that improve efficiency, cut back weight, and reduce environmental impression, thereby:

– Optimizing Efficiency: Custom-made parts that enhance automobile dynamics and cut back manufacturing prices.

– Decreasing Emissions: Light-weight parts that contribute to diminished gas consumption and decrease carbon emissions.

– Enhancing Security: Advanced parts that enhance automobile security options, resembling airbags and crash buildings.

Shopper Items: Democratizing Innovation

The buyer items business has leveraged 3D printing to create {custom} merchandise, enabling customers to take management of the design and manufacturing course of, thus:

– Empowering Creativity: Customers can design and produce merchandise that replicate their individuality and elegance.

– Optimizing Effectivity: Diminished manufacturing prices and lead instances, enabling sooner turnaround instances for custom-made merchandise.

– Encouraging Sustainability: Minimized waste and diminished environmental impression by the discount of packaging and transport necessities.

Examples of 3D Printed Gadgets in Schooling and Analysis

3D printing has revolutionized the tutorial sector by offering college students with hands-on expertise in numerous topics, resembling arithmetic and science. Academic establishments have been actively adopting 3D printing know-how to boost instructing strategies, enhance pupil engagement, and foster creativity. From creating custom-made fashions and replicas to creating interactive studying aids, 3D printed gadgets have grow to be an important software in trendy school rooms.

Case Research in Academic Settings

A number of instructional establishments have efficiently built-in 3D printing know-how into their curriculum, yielding spectacular outcomes. For example, college students on the College of California, Los Angeles (UCLA) used 3D printing to create custom-made prosthetics for youngsters with amputations. This undertaking not solely supplied college students with sensible expertise in 3D printing but in addition made a tangible distinction within the lives of their younger beneficiaries. Equally, a gaggle of highschool college students in the USA efficiently designed and 3D printed a mannequin of the human coronary heart, which helped them higher perceive anatomy and recognize the intricacies of cardiovascular biology.

Examples of 3D Printed Gadgets in Analysis Services

Analysis amenities have additionally been leveraging 3D printing know-how to create complicated prototypes and fashions for numerous scientific functions. For instance, researchers on the College of Oxford used 3D printing to create a custom-made cranium implant for a affected person affected by a uncommon bone dysfunction. This progressive strategy allowed the researchers to exactly reproduce the affected person’s cranium construction, paving the way in which for simpler remedy choices.

Advantages of Utilizing 3D Printing in Educating and Analysis

The usage of 3D printing know-how in instructional settings and analysis amenities presents quite a few advantages, together with:

- Enhanced pupil engagement and motivation: 3D printing gives college students with an interactive and hands-on expertise, permitting them to discover complicated ideas in a extra participating and significant method.

- Improved information retention and understanding: By creating tangible fashions and replicas, college students can higher grasp summary ideas and concepts, resulting in improved information retention and comprehension.

- Elevated creativity and innovation: 3D printing know-how empowers college students and researchers to suppose creatively and develop progressive options to complicated issues.

- Diminished prices and improved effectivity: 3D printing permits for speedy prototyping and manufacturing, decreasing prices and enhancing effectivity in analysis and academic settings.

Future Purposes and Traits in Schooling and Analysis

As 3D printing know-how continues to evolve, it’s prone to have a profound impression on numerous sectors, together with schooling and analysis. Future functions and developments could embody:

- Elevated adoption of 3D printing in distant and underserved areas, enabling entry to 3D printing know-how for college kids and researchers worldwide.

- Improvement of personalised studying experiences, tailor-made to particular person college students’ wants and studying types.

- Enhanced collaboration and co-creation amongst college students, researchers, and business professionals, facilitated by 3D printing know-how.

- Integration of synthetic intelligence and machine studying in 3D printing, enabling the creation of complicated and customised gadgets with unprecedented accuracy.

Creating Custom-made 3D Printed Gadgets

Within the realm of 3D printing, customization is the important thing to unlocking a world of progressive prospects. By harnessing the facility of cutting-edge design instruments and methods, people can carry their distinctive concepts to life, creating bespoke gadgets that replicate their individuality and aptitude. This strategy of custom-made 3D printing includes a multi-disciplinary strategy, incorporating parts of design, engineering, and supplies science.

Designing Custom-made 3D Printed Gadgets

The method of making custom-made 3D printed gadgets begins with the design stage, the place people can leverage a spread of software program instruments to carry their imaginative and prescient to life. A few of the hottest design instruments for 3D printing embody

- Laptop-Aided Design (CAD) software program, resembling Tinkercad, Fusion 360, or Blender, which allow customers to create complicated geometric shapes and curves.

- Laptop-Aided Manufacturing (CAM) software program, resembling Simplify3D or Cura, which concentrate on making ready the 3D mannequin for printing.

These instruments provide an unlimited array of options, together with parametric design, boolean operations, and mesh modeling, permitting customers to craft intricate and customised designs. By using these software program options, people can create 3D fashions that not solely meet however exceed their expectations.

Using Design Software program for Customization

Along with CAD and CAM software program, designers may also make use of a wide range of different instruments to boost their {custom} 3D printed creations. These embody

- Parametric design software program, resembling Grasshopper or Dynamo, which allow customers to create complicated methods and relationships between totally different design parts.

- Scripting languages, resembling Python or JavaScript, which can be utilized to automate customizations and improve the design course of.

These instruments empower designers to push the boundaries of 3D printing, enabling them to create intricate, custom-made gadgets that showcase their creativity and experience.

Submit-Processing Methods

As soon as the design stage is full, the subsequent step includes making ready the 3D mannequin for printing. This includes changing the design right into a format that may be learn by the 3D printing machine, choosing the optimum printing settings, and adjusting the layer thickness and infill density as per necessities. Submit-processing methods additionally play a vital function in enhancing the looks and performance of the ultimate printed merchandise.

Greatest Practices for Submit-Processing 3D Printed Gadgets

Submit-processing is an important step within the 3D printing course of, because it enhances the aesthetic high quality and sturdiness of the ultimate product. A well-executed post-processing course of can elevate a merely purposeful merchandise right into a visually interesting murals. Whether or not you’re a seasoned 3D printing fanatic or a newcomer to the world of additive manufacturing, understanding finest practices for post-processing 3D printed gadgets is essential for attaining a high-quality end.

Cleansing the Floor

Step one in post-processing 3D printed gadgets is to wash the floor of any particles, resin residue, or help materials. That is essential in making certain a easy end and stopping any imperfections. There are a number of methods for cleansing the floor, together with:

- Disregarding free particles with a soft-bristled brush

- Utilizing a mild cleansing resolution and a delicate material to wipe down the floor

- Using compressed air or a vacuum cleaner to take away mud and particles

Relying on the fabric and complexity of the print, some prints could require extra aggressive cleansing strategies, resembling sanding or grinding.

Sanding and Smoothing, Greatest 3d printed gadgets

Sanding and smoothing the floor of 3D printed gadgets helps to take away any tough edges or burrs, making a easy, even end. This step is crucial for attaining a high-quality end and making ready the merchandise for portray or different coatings. There are a number of forms of sandpaper and abrasive supplies that can be utilized for this job, together with:

- Coarse-grit sandpaper (80-100 grit) for eradicating massive imperfections

- Medium-grit sandpaper (220-240 grit) for smoothing out the floor

- High-quality-grit sandpaper (320-400 grit) for sprucing the floor

It’s important to work progressively by the grits, beginning with a rough grit and shifting to finer grits, to keep away from creating scratches or swirl marks.

Portray and Coating

As soon as the floor has been cleaned and sanded, it may be painted or coated with numerous supplies to boost the looks and sturdiness of the merchandise. This step requires cautious planning and preparation to attain the specified outcomes. There are a number of forms of paints and coatings that can be utilized, together with:

- Acrylic paint for a sturdy, shiny end

- Enamel paint for a high-gloss, sturdy end

- Clear coat for added sturdiness and safety

It’s important to observe the producer’s directions for utility and curing to make sure the perfect outcomes.

Protecting Coatings

Along with portray and coating, protecting coatings will be utilized to 3D printed gadgets to boost their sturdiness and resistance to put on and tear. Some frequent forms of protecting coatings embody:

- Epoxies for added power and sturdiness

- Acrylic varnish for a transparent, protecting end

- Silicone-based coatings for a water-repellent end

These coatings will be utilized in numerous methods, together with spraying, brushing, or dipping, and will require curing or drying earlier than they’re absolutely efficient.

Future Developments in 3D Printing Expertise

![Top Selling 3D Printed Items on Etsy [2024] 🚀 - 3D Printed Best 3d printed items](https://www.3d-printed.org/wp-content/uploads/2024/03/photo-1680539208269-e7c8898c0713cropentropycstinysrgbfitmaxfmjpgixidM3w0NDMxOTh8MHwxfHNlYXJjaHwyfHwzZCUyMHByaW50ZWQlMjBpdGVtcyUyMG9uJTIwZXRzeXxlbnwwfHx8fDE3MDk1NTI2NTB8MAixlibrb-4.0.jpg)

As we navigate the uncharted territories of innovation, the realm of 3D printing continues to evolve at an unprecedented tempo. The way forward for this know-how holds countless prospects, with rising developments and improvements poised to revolutionize numerous industries and points of our each day lives. On this exploration, we are going to delve into the thrilling developments which might be anticipated to form the way forward for 3D printing and propel this know-how to unimaginable heights.

Developments in Supplies and Applied sciences

The continued quest for progressive supplies and applied sciences has led to important breakthroughs in 3D printing. Researchers and producers at the moment are specializing in creating new supplies with enhanced properties, resembling power, sturdiness, and conductivity. A few of the most promising developments embody:

- Graphene-based composites, boasting distinctive strength-to-weight ratios and electrical conductivity.

- Bio-based polymers derived from plant-based renewable assets, providing a extra sustainable different to conventional plastics.

- Form-memory alloys able to altering form in response to temperature or electrical stimuli, enabling the creation of complicated geometries and buildings.

- 4D printing, a know-how that mixes 3D printing with non permanent, reversible modifications in materials properties, permitting for the creation of self-reconfiguring and self-healing buildings.

These innovating supplies and applied sciences will allow the event of complicated and dynamic methods, paving the way in which for groundbreaking functions in numerous fields.

The Rise of Additive Manufacturing 4.0

The convergence of industrial-grade 3D printing, synthetic intelligence, and the Web of Issues (IoT) is giving delivery to Additive Manufacturing 4.0. This next-generation know-how will allow the creation of built-in, autonomous manufacturing methods that may optimize manufacturing processes, predict and forestall defects, and constantly enhance product high quality. The impression of Additive Manufacturing 4.0 can be felt throughout industries, from aerospace and automotive to healthcare and shopper items.

The combination of AI and IoT in Additive Manufacturing 4.0 will revolutionize the manufacturing panorama by enabling real-time monitoring, predictive upkeep, and autonomous manufacturing management.

The Way forward for 3D Printing in Area Exploration

As house exploration continues to push the boundaries of human ingenuity, 3D printing is enjoying a significant function within the growth of sustainable and modular spacecraft. The flexibility to create complicated buildings and methods on-site utilizing 3D printing will allow astronauts to assemble habitats, instruments, and different important parts in distant or hostile environments. This know-how has far-reaching implications for planetary colonization and the prospect of creating human settlements on the Moon, Mars, and different celestial our bodies.

The usage of 3D printing in house exploration will pave the way in which for the creation of modular, self-sustaining habitats and methods that may adapt to the challenges of extraterrestrial environments.

Conclusion

The way forward for 3D printing is a canvas of countless prospects, with rising developments and improvements poised to revolutionize numerous industries and points of our each day lives. As we proceed to discover the uncharted territories of this know-how, we are able to anticipate to see important breakthroughs in supplies, applied sciences, and functions. The probabilities are countless, and the way forward for 3D printing is brilliant and limitless.

Conclusive Ideas

In conclusion, the world of 3D printed gadgets is a realm of countless prospects and creativity, providing a glimpse into the way forward for innovation and self-expression. Whether or not used for sensible functions or as a type of inventive expression, 3D printed gadgets proceed to form and encourage us in numerous methods.

FAQ Overview: Greatest 3d Printed Gadgets

What are the advantages of 3D printing?

Price-effectiveness, customization, and sustainability are a number of the key advantages of 3D printing.

How does 3D printing cut back environmental impression?

3D printing know-how can cut back environmental impression by minimizing waste, decreasing materials utilization, and reducing provide chain complexity.

What forms of supplies can be utilized in 3D printing?

3D printing can use a wide range of supplies, together with plastics, metals, ceramics, and glass.