Finest double sided adhesive tape, the unsung hero of the adhesives world, has been revolutionizing the way in which we bond supplies for many years. From family duties to industrial purposes, its versatility and reliability have made it an indispensable instrument in each nook of our lives.

With a variety of sorts and purposes, double sided adhesive tape has grow to be a vital part in varied industries, together with building, automotive, aerospace, and electronics.

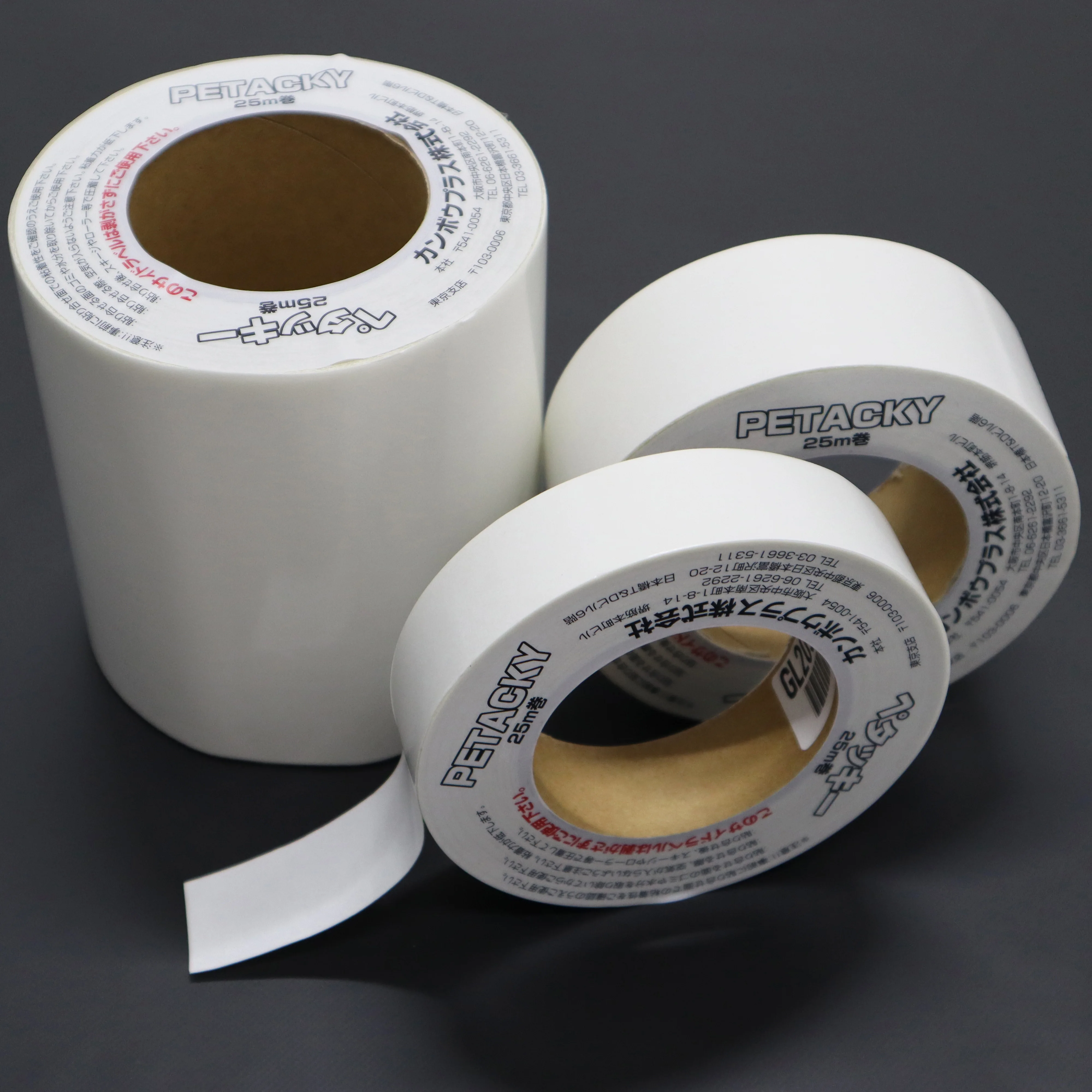

Sorts of Double Sided Adhesive Tape

Double sided adhesive tapes have grow to be a vital part of assorted industries, on account of their versatility and comfort in securing objects collectively. With quite a few sorts accessible, deciding on the correct one could be daunting, particularly for these unfamiliar with the product. Understanding the several types of double sided adhesive tapes is essential for selecting the best choice for particular purposes.

Customary Double Sided Tape

Customary double sided tape, also referred to as general-purpose tape, is without doubt one of the most generally accessible and generally used varieties of double sided adhesive tapes. It’s usually product of a skinny, foam-backed adhesive, which is light on surfaces and simple to peel off with out leaving residue. Customary double sided tape is appropriate for a spread of purposes, together with mounting light-weight objects, securing small gadgets in place, and crafting. A number of the widespread purposes of ordinary double sided tape embrace:

- Mounting LED lights and fixtures

- Securing small electronics and parts

- Creating DIY crafts and decorations

- Mounting light-weight indicators and banners

Strengthened Double Sided Tape

Strengthened double sided tape is designed for heavy-duty purposes, offering elevated energy and sturdiness in comparison with commonplace double sided tape. It’s made with a thicker, extra aggressive adhesive and a bolstered backing, making it appropriate for securing heavier objects. Strengthened double sided tape is often utilized in industries comparable to building, manufacturing, and logistics, the place heavy-duty adhesion is required. A number of the advantages of bolstered double sided tape for heavy-duty use embrace:

- Elevated tensile energy and sturdiness

- Improved adhesion to a wide range of surfaces

- Immune to shock and vibration

- Simple to use and take away with out leaving residue

Customized Double Sided Tape

Customized double sided tape is designed for particular industries or purposes, providing distinctive properties and options tailor-made to fulfill the wants of the person. For instance, a customized double sided tape for the automotive trade might need a silicone-based adhesive and a heavy-duty backing, whereas one for the electronics trade might need a foam-backed adhesive and a low-profile backing. Customized double sided tapes could be designed to fulfill particular necessities, comparable to:

- Resistance to excessive temperatures

- Adhesion to particular surfaces, comparable to plastics or metals

- Low-profile backing for hid purposes

- Excessive-temperature resistance for purposes in kiln or oven

Static conductive and non-static double sided tapes are designed for purposes the place static electrical energy could be a concern. Static conductive double sided tape is made with a conductive backing, which prevents the buildup of static electrical energy, making it preferrred for purposes in environments with excessive humidity or risky chemical compounds. Non-static double sided tape, however, is designed for purposes the place static electrical energy shouldn’t be a priority, typically with a non-conductive backing. A number of the variations between static-conductive and non-static double sided tape embrace:

- Conductive backing vs non-conductive backing

- Prevents buildup of static electrical energy vs no static prevention

- Designed for high-humidity or risky chemical environments vs general-purpose purposes

Components Affecting Double Sided Adhesive Tape Efficiency

Double sided adhesive tapes have grow to be a vital part in varied industries, from manufacturing to building, on account of their versatility and ease of use. Nonetheless, their efficiency could be influenced by a number of elements, making it essential to grasp these elements to realize optimum outcomes. Environmental elements, particularly, can considerably affect the adhesion properties of double sided tapes.

Environmental Components Influencing Double Sided Tape Adhesion

Environmental elements could cause modifications in temperature and humidity, affecting the adhesive properties of double sided tape. Temperature could cause the adhesive to melt, making it extra vulnerable to lack of adhesion, or harden, decreasing its stickiness. Equally, humidity could cause the adhesive to grow to be weak or brittle. Publicity to water, chemical compounds, or excessive temperatures can additional degrade the adhesive properties of double sided tape.

Temperature and Humidity Impression on Double Sided Tape Adhesive Properties

Temperature and humidity can considerably affect the adhesive properties of double sided tape. The perfect temperature vary for many double sided tapes is between 50°F to 80°F (10°C to 27°C), whereas excessive temperatures above 120°F (49°C) could cause the adhesive to melt and lose its stickiness. However, low temperatures under 32°F (0°C) could cause the adhesive to harden, decreasing its adhesion properties.

Getting older and UV Publicity Results on Double Sided Tape Efficiency

Double sided tape also can expertise degradation on account of ageing and UV publicity. Because the tape ages, its adhesive properties can weaken, and its stickiness can lower. UV publicity could cause the adhesive to interrupt down, resulting in a lack of adhesion and lowered efficiency.

To guage the sturdiness of double sided tape, varied testing strategies could be employed. These embrace:

- Tensile energy testing: This measures the power required to stretch or break the tape.

- Adhesion testing: This measures the power required to separate the tape from the substrate.

- Environmental testing: This includes exposing the tape to totally different environmental circumstances, comparable to temperature and humidity, to evaluate its efficiency.

- UV publicity testing: This includes exposing the tape to UV gentle to evaluate its resistance to degradation.

By understanding these elements and testing strategies, producers and customers can optimize the efficiency and sturdiness of double sided tapes, guaranteeing they meet the required requirements for varied purposes.

Testing and Analysis Strategies for Double Sided Tape Sturdiness

The next are a number of the testing strategies used to guage the sturdiness of double sided tape:

Tensile energy testing could be carried out utilizing a tensile energy testing machine, which applies a power to the tape till it breaks, measuring the power required to interrupt the tape.

- Peel testing: This includes peeling the tape from the substrate at a selected angle and pace to measure the power required to separate the tape from the substrate.

- Shear testing: This includes making use of a power to the tape in a course parallel to the floor, measuring the power required to trigger failure.

- Creep testing: This includes making use of a relentless power to the tape over a time period to evaluate its capacity to withstand deformation.

By understanding the elements that have an effect on double sided tape efficiency and utilizing varied testing strategies to guage its sturdiness, producers and customers can optimize the efficiency and lifespan of double sided tapes for a variety of purposes.

Frequent Misuses of Double Sided Adhesive Tape

Double sided adhesive tape is broadly utilized in varied industries on account of its versatility and comfort. Nonetheless, improper utilization of double sided tape can result in catastrophic penalties, together with injury to supplies, gear, and even human security. On this part, we are going to talk about some widespread misuses of double sided adhesive tape and their potential penalties.

Load-Bearing Purposes

One of the crucial crucial misuses of double sided tape is its utility in load-bearing eventualities. Double sided tape shouldn’t be designed to hold heavy masses or bear vital weights, and its adhesive properties can simply fail below such circumstances. When utilized in load-bearing purposes, double sided tape can result in sudden failures, inflicting accidents, accidents, and even fatalities.

For example, a research performed by the Nationwide Institute of Requirements and Expertise discovered that double sided tape failed to keep up its adhesive properties when subjected to masses exceeding 10 kilos per sq. inch (PSI). In distinction, industrial adhesives designed for load-bearing purposes can stand up to masses as much as 1000 PSI or extra. This vital distinction highlights the significance of choosing the right kind of adhesive for every particular utility.

Uneven or Contaminated Surfaces, Finest double sided adhesive tape

One other widespread misuse of double sided tape is its utility on uneven or contaminated surfaces. When used on such surfaces, double sided tape can fails to stick correctly, resulting in a lower in its total efficiency and probably inflicting accidents.

If the floor is uneven, the tape could not be capable of distribute the adhesive evenly, leading to a weak bond. Equally, if the floor is contaminated with filth, oil, or different substances, the adhesive could not be capable of bond correctly, resulting in a lack of adhesion.

To keep away from these points, it’s important to make sure that the floor is clear, dry, and free from contaminants earlier than making use of double sided tape.

Flawed Sort of Double Sided Tape

Utilizing the mistaken kind of double sided tape for a selected utility is one other widespread mistake that may result in critical penalties. Various kinds of double sided tapes are designed for particular functions, comparable to static dissipation, high-temperature purposes, or chemical resistance.

Utilizing the mistaken kind of tape can result in a lower in adhesion, a failure to carry out the specified perform, or perhaps a launch of poisonous chemical compounds. For instance, utilizing a double sided tape designed for static dissipation on a high-temperature utility can result in a discount in its adhesive properties and probably trigger gear failure.

To keep away from these points, it’s essential to pick the right kind of double sided tape for every particular utility, making an allowance for elements comparable to temperature, humidity, and the kind of floor being bonded.

Significance of Following Producer’s Directions

Lastly, it’s important to comply with the producer’s directions when utilizing double sided tape. The producer’s directions present crucial details about the tape’s properties, limitations, and really helpful makes use of.

Ignoring these directions can result in a lower within the tape’s efficiency, issues of safety, or gear injury. For instance, exceeding the really helpful temperature vary for a selected kind of double sided tape could cause it to degrade or lose its adhesive properties.

To make sure the secure and efficient use of double sided tape, it’s important to comply with the producer’s directions and pointers. This may assist forestall accidents, guarantee gear security, and preserve the integrity of the supplies being bonded.

Finest Practices for Making use of Double Sided Adhesive Tape

Making use of double sided adhesive tape easily and evenly is essential for its optimum efficiency and to keep away from any potential points comparable to injury to the supplies being held collectively. A number of key steps could be adopted to make sure a profitable utility course of, ranging from correct floor preparation to sustaining the right adhesive temperature.

Correct Floor Preparation and Temperature Management

Correct floor preparation is important to make sure a robust bond between the double sided tape and the surfaces it’s utilized to. This consists of cleansing the surfaces to take away any filth, oil, or different substances which will intrude with the adhesive. Moreover, it’s essential to keep up the really helpful adhesive temperature, which is normally between 20°C to 30°C (68°F to 86°F) for many double sided tapes. This temperature vary ensures optimum bonding and reduces the chance of the adhesive changing into too delicate or too laborious, which may result in a weak bond and even failure.

Step-by-Step Procedures for Making use of Double Sided Tape

The next are the step-by-step procedures for making use of double sided tape:

- Clear the surfaces that may come into contact with the double sided tape.

- Peel the backing off the double sided tape, however solely the highest aspect that isn’t but involved with the floor.

Frequent Errors to Keep away from

There are just a few widespread errors to keep away from when making use of double sided tape, together with making use of the tape with the backing nonetheless on, making use of an excessive amount of strain which may trigger the adhesive to grow to be too delicate, or inserting the tape in direct daylight or excessive temperatures. Additionally it is important to comply with the producer’s directions for any particular suggestions on floor preparation and utility procedures.

Particular Concerns for Strengthened Double Sided Tape

When utilizing bolstered double sided tape, it’s essential to take just a few further steps to make sure correct utility, together with:

- Peel the backing from the bolstered aspect, reasonably than the highest aspect, to forestall any attainable injury to the reinforcement.

Business-Particular Makes use of for Double Sided Adhesive Tape

Double sided adhesive tape has a variety of purposes throughout varied industries, every with its distinctive set of challenges and necessities. These versatile adhesives have grow to be a vital part within the manufacturing and manufacturing processes of quite a few sectors, enabling environment friendly product creation and dependable efficiency.

The Automotive Business

The automotive trade closely depends on double sided adhesive tape for varied purposes, together with part attachment, sealants, and noise discount. On this trade, double sided tape is important for securing parts comparable to dashboard trim, seatbelts, and wiring harnesses, guaranteeing a safe match and withstanding the pains of the driving surroundings.

- Weight discount: Double sided tape is commonly used to connect light-weight parts, comparable to carbon fiber panels, to the automobile chassis, decreasing total weight and bettering gas effectivity.

- Acoustic insulation: The tape is used to reduce noise air pollution by attaching sound-absorbing supplies to the automobile’s inside, enhancing passenger consolation.

- Electrical insulation: Double sided tape ensures correct insulation between electrical parts, decreasing the chance {of electrical} shock and different hazards.

The Aerospace Business

The aerospace trade additionally depends on double sided adhesive tape for part attachment, sealants, and thermal administration. The tape’s excessive temperature resistance and energy make it preferrred for purposes in excessive environments.

- Part integration: Double sided tape is used to connect complicated parts, comparable to satellite tv for pc panels and antennae, to spacecraft constructions.

- Thermal administration: The tape helps to dissipate warmth from digital parts, decreasing the chance of overheating and gear failure.

- Sealing: Double sided tape is used to seal gaps and guarantee hermetic connections between parts, stopping the lack of crucial fluids or gases.

The Development and Fabrication Industries

Double sided adhesive tape performs an important function within the building and fabrication industries, notably in purposes comparable to roofing, insulation, and ornamental trim. The tape’s versatility and ease of use make it a well-liked selection for tradespeople and DIY lovers.

- Roofing: Double sided tape is used to safe roofing supplies, comparable to shingles, panels, and tiles, guaranteeing a weather-tight seal.

- Insulation: The tape helps to retain insulation supplies, comparable to fiberglass and foam board, in place, decreasing vitality loss and warmth switch.

- Ornamental trim: Double sided tape is used to connect ornamental trim, comparable to molding and edging, to partitions and ceilings, offering a clear and completed look.

The Electronics Business

Double sided adhesive tape is an important part within the electronics trade, notably in purposes comparable to PCB meeting, part attachment, and thermal administration. The tape’s precision and reliability make it a necessary instrument for electronics producers.

Medical Machine Purposes

Double sided adhesive tape has a spread of purposes within the medical system trade, together with part attachment, wound care, and implantable gadgets. The tape’s biocompatibility and sturdiness make it a really perfect selection for medical purposes.

- Wound care: Double sided tape is used to safe dressings and bandages, guaranteeing a safe match and selling wound therapeutic.

- Part attachment: The tape is used to connect medical gadgets, comparable to electrodes and sensors, to the pores and skin, guaranteeing a safe and dependable connection.

- Implantable gadgets: Double sided tape is used to connect implantable gadgets, comparable to pacemakers and prosthetics, to the physique, guaranteeing a safe and comfy match.

Improvements in Double Sided Adhesive Tape Expertise: Finest Double Sided Adhesive Tape

The event of double sided adhesive tape know-how has been a quickly evolving discipline, with quite a few improvements geared toward bettering its efficiency, sturdiness, and sustainability. From high-strength double sided tapes to biodegradable choices, the trade has witnessed vital developments in recent times. This part will delve into the newest developments in double sided adhesive tape know-how, highlighting key improvements and their advantages.

Developments in Excessive-Energy Double Sided Tape

Excessive-strength double sided tape has gained vital consideration in varied industries, together with aerospace, automotive, and building. These tapes are designed to supply distinctive bonding energy, resistance to excessive temperatures, and sturdiness in harsh environments. Current improvements in high-strength double sided tape have led to the event of tapes with improved tensile energy, peel resistance, and shear energy. For example, some high-strength double sided tapes now boast tensile strengths of as much as 100 kilos per sq. inch (psi), making them appropriate for heavy-duty purposes.

- Tensile energy: Excessive-strength double sided tape now affords tensile strengths of as much as 100 psi, making it preferrred for heavy-duty purposes.

- Improved resistance: These tapes exhibit enhanced resistance to warmth, chemical compounds, and UV radiation, guaranteeing an extended lifespan.

- Enhanced adhesion: With the introduction of superior adhesives, these tapes show improved adhesion on a wide range of surfaces, decreasing the chance of delamination.

- Decreased weight: Light-weight high-strength double sided tape variations have been developed, which are perfect for purposes the place weight is a significant concern.

Advantages of Biodegradable Double Sided Tape

Lately, there was a rising demand for biodegradable supplies in varied industries. Biodegradable double sided tape has emerged as a sustainable different to conventional tapes, providing a number of advantages. These tapes are designed to decompose naturally, decreasing the quantity of plastic waste and minimizing environmental affect. Biodegradable double sided tape can be non-toxic, making it a safer possibility for purposes the place publicity to chemical compounds is a priority.

- Decreased waste: Biodegradable double sided tape considerably reduces plastic waste, contributing to a cleaner surroundings.

- Non-toxic: Any such tape is non-toxic, guaranteeing a safer working surroundings, particularly in purposes the place publicity to chemical compounds is a priority.

- Eco-friendly: Biodegradable double sided tape is produced from bioplastics, that are derived from renewable sources, making it a sustainable possibility.

- Low carbon footprint: The manufacturing technique of biodegradable double sided tape has a decrease carbon footprint in comparison with conventional tapes.

Examples of Double Sided Tape with Improved Insulation or Thermal Conductivity Properties

Double sided tape has been utilized in varied insulation and thermal conductivity purposes, together with roofing, piping, and electrical techniques. Current improvements have led to the event of tapes with improved thermal insulation properties, decreasing warmth switch and vitality loss. However, some tapes have been designed to exhibit excessive thermal conductivity, making them appropriate for warmth sink purposes.

- Thermal insulation: Double sided tape with improved thermal insulation properties has been developed for roofing and piping purposes.

- Excessive-thermal conductivity: Tapes with excessive thermal conductivity have been designed for warmth sink purposes, comparable to electronics and aerospace.

- Multi-functional: Some tapes now mix thermal insulation and electrical insulation properties, making them appropriate for a variety of purposes.

- Hearth resistance: Some high-thermal conductivity tapes have additionally been designed to supply hearth resistance, decreasing the chance of fireplace spreading.

Comparability of Stress-Delicate Adhesives and Reactive Adhesives

Double sided tape could be categorized into two primary sorts based mostly on the adhesive used: pressure-sensitive adhesives (PSAs) and reactive adhesives. PSAs are broadly utilized in double sided tape purposes on account of their ease of use, flexibility, and fast bonding properties. Reactive adhesives, however, supply improved sturdiness and thermal resistance, making them appropriate for purposes the place high-temperature publicity is a priority.

Reactive adhesives supply improved sturdiness and thermal resistance in comparison with pressure-sensitive adhesives.

- Simple to make use of: Stress-sensitive adhesives are broadly used on account of their ease of utility and fast bonding properties.

- Flexibility: PSAs exhibit wonderful flexibility, making them appropriate for purposes with various floor shapes or uneven surfaces.

- Improved adhesion: Stress-sensitive adhesives usually supply improved adhesion on varied surfaces, together with plastics, metals, and glass.

- Value-effective: PSAs are typically more cost effective in comparison with reactive adhesives.

- Improved sturdiness: Reactive adhesives supply improved sturdiness and thermal resistance, making them appropriate for high-temperature purposes.

- Decreased creep: Reactive adhesives exhibit lowered creep, minimizing the chance of adhesive separation below mechanical stress.

- Enhanced stability: Reactive adhesives supply enhanced stability, guaranteeing constant bonding properties over time.

- Excessive-temperature resistance: These adhesives are designed to exhibit high-temperature resistance, making them appropriate for purposes the place excessive temperatures are concerned.

Ending Remarks

As we conclude our dialogue on finest double sided adhesive tape, we hope you’ve got gained beneficial insights into its traits, purposes, and finest practices. Bear in mind, the correct adhesive tape could make all of the distinction in your subsequent undertaking. Select properly, bond strongly, and create one thing wonderful!

FAQ Abstract

Q: What’s the most temperature vary for finest double sided adhesive tape?

A: The utmost temperature vary varies relying on the sort and producer, however typically, it ranges from -20°C to 80°C (-4°F to 176°F) for most traditional double sided tapes.

Q: Can I exploit double sided adhesive tape on tough or uneven surfaces?

A: No, it is not really helpful to make use of double sided tape on tough or uneven surfaces, as it could compromise the bonding course of. All the time make sure the floor is clear, dry, and easy.

Q: How do I get rid of used double sided adhesive tape?

A: Reduce the tape into smaller items and get rid of it within the trash. Keep away from tearing or stretching the tape, as it could trigger it to lose its adhesive properties.