Delving into greatest adhesive for plastic, this introduction immerses readers in a novel and compelling narrative, describing the significance of choosing the proper adhesive for varied purposes. On this complete overview, we’ll discover the important elements to contemplate when choosing an adhesive for plastic supplies.

Using adhesives for plastic has turn into a pivotal facet of contemporary manufacturing, significantly in industries akin to engineering, electronics, and crafts. Understanding the properties and traits of various adhesives is essential for reaching robust, sturdy bonds that meet particular necessities.

Finest Adhesive for Plastic: Selecting the Proper Choices

With the quite a few sorts of adhesives out there for plastic, choosing the perfect one may be overwhelming. That is very true contemplating the assorted elements at play when selecting an adhesive. From the particular sort of plastic to the specified utility and environmental situations, it is essential to contemplate every factor to make sure the absolute best final result.

Frequent Forms of Adhesives for Plastic

The kind of adhesive used typically is dependent upon the particular necessities of the plastic being bonded. Listed here are some generally used adhesives for plastic:

- Epoxy adhesives: These present glorious power, sturdiness, and resistance to warmth, chemical substances, and influence. They arrive in quite a lot of formulations, from low-viscosity to high-viscosity, making them appropriate for a variety of purposes.

- Acrylic adhesives: These supply good bonding power, flexibility, and resistance to UV and warmth. They’re generally used for bonding PVC, ABS, and different acrylic plastics.

- Polyurethane adhesives: These present good bonding power, flexibility, and resistance to chemical substances and abrasion. They’re typically used for bonding polyurethane, PVC, and different versatile plastics.

Components to Take into account When Selecting an Adhesive

When choosing an adhesive for plastic, it is important to contemplate a number of elements to make sure the absolute best final result. Listed here are some key concerns:

- Bond power: The adhesive ought to present ample bonding power to satisfy the necessities of the applying.

- Environmental situations: Take into account the temperature, humidity, and publicity to chemical substances and UV that the adhesive might be topic to.

- Plastic sort: The adhesive ought to be appropriate with the kind of plastic being bonded.

- Utility technique: Take into account the benefit of utility, together with the instruments and gear required.

- Curing time: The adhesive ought to remedy shortly, or on the very least, to the specified extent.

Compatibility and Testing

Earlier than choosing an adhesive, it is essential to make sure compatibility with the particular plastic materials. Listed here are some further concerns:

- Seek the advice of the producer’s suggestions for adhesive compatibility with the plastic materials.

- Carry out assessments to make sure the adhesive meets the required bonding power and sturdiness.

- Take into account the adhesive’s compatibility with different supplies that could be current within the utility, akin to coatings or substrates.

Chemical Properties of Adhesives for Plastic

With regards to choosing the proper adhesive for plastic, understanding the chemical properties is essential for a powerful and sturdy bond. Adhesives for plastic may be broadly categorized into differing types, every possessing distinct traits that make them appropriate for particular purposes.

Epoxy Adhesives

Epoxy adhesives are identified for his or her robust bonding capabilities, making them excellent for high-stress purposes. They’re shaped from a mix of epoxy resin and hardener. The curing course of includes a chemical response between the 2 elements, leading to a inflexible and robust bond. Epoxy adhesives are additionally proof against warmth, chemical substances, and abrasion, which makes them appropriate for purposes in harsh environments.

Acrylic Adhesives

Acrylic adhesives, then again, are identified for his or her flexibility and flexibility. They’re shaped from a mix of monomers, which polymerize to type a versatile and robust bond. Acrylic adhesives are sometimes utilized in purposes the place flexibility and absorbency are required, akin to in medical gadgets and absorbent pads. They’re additionally proof against chemical substances and may stand up to publicity to oils and greases.

PU (Polyurethane) Adhesives

PU adhesives are identified for his or her excessive bonding power and adaptability. They’re shaped from a mix of polyols and isocyanates, which polymerize to type a powerful and versatile bond. PU adhesives are sometimes utilized in purposes the place excessive bonding power and adaptability are required, akin to in footwear and automotive industries.

PVA (Polyvinyl Acetate) Adhesives

PVA adhesives are identified for his or her water-soluble and versatile properties. They’re shaped from a mix of water and PVA dispersion, which polymerize to type a versatile and robust bond. PVA adhesives are sometimes utilized in purposes the place water-soluble adhesives are required, akin to in paper and bookbinding industries.

Adhesive Composition and Bonding Power

The composition of an adhesive can considerably have an effect on its bonding power and sturdiness. The collection of uncooked supplies, akin to resins, hardeners, and plasticizers, can affect the adhesive’s chemical properties and efficiency. The ratio of those elements may also influence the bonding power and adaptability of the adhesive. For instance, the next ratio of hardener to resin may end up in a stronger bond, however can also make the adhesive extra brittle.

Adhesive Composition and Sturdiness

The sturdiness of an adhesive can be depending on its chemical composition. The collection of UV stabilizers, antioxidants, and different components can affect the adhesive’s resistance to warmth, mild, and chemical substances. A well-balanced composition can make sure that the adhesive stays versatile and robust over time, even when uncovered to harsh environmental situations.

“The collection of the proper adhesive for a particular utility is essential to making sure the power and sturdiness of the bond. Understanding the chemical properties of adhesives is crucial for making knowledgeable selections.”

Finest Adhesives for Plastic by Utility

With regards to choosing the proper adhesive for plastic, understanding the applying is essential. Totally different adhesives are suited to varied duties, and the proper alternative could make all of the distinction.

Adhesives are utilized in a variety of purposes, together with engineering, electronics, and crafts. For instance, within the engineering business, adhesives are used to bond light-weight supplies akin to carbon fiber and composites. In electronics, adhesives are used to connect elements to circuit boards and to bond dissimilar plastics. In crafts, adhesives are used to create ornamental objects and restore broken plastics.

Bonding Dissimilar Plastics

With regards to bonding dissimilar plastics, the selection of adhesive is essential. Some standard choices embrace:

- Epoxy adhesives: These are two-part adhesives that harden when combined collectively. They provide glorious bonding power and are sometimes used to bond plastics akin to polycarbonate and acrylic.

- Acylic adhesives: These are solvent-based adhesives that dry shortly and supply good bonding power.

- Mechanical adhesives: These adhesives use mechanical fasteners akin to screws or nuts to safe the bond.

These adhesives are sometimes utilized in purposes the place excessive power and sturdiness are required, akin to within the aerospace and automotive industries.

Attaching Light-weight Supplies

With regards to attaching light-weight supplies akin to carbon fiber and composites, the selection of adhesive can be essential. Some standard choices embrace:

- Two-component epoxy adhesives: These adhesives supply glorious bonding power and are sometimes used to bond carbon fiber and composites.

- Acrylic adhesives: These adhesives are solvent-based and supply good bonding power.

- Urethane adhesives: These adhesives are versatile and supply good vibration damping properties, making them excellent for purposes the place shock absorption is required.

These adhesives are sometimes utilized in purposes the place excessive power and sturdiness are required, akin to within the aerospace and automotive industries.

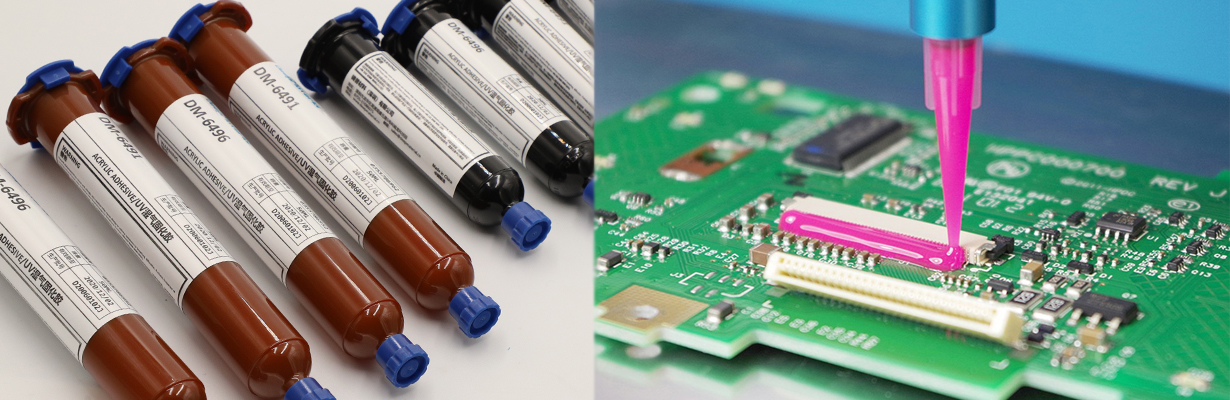

Electronics and Circuit Board Meeting

In electronics, adhesives are used to connect elements to circuit boards and to bond dissimilar plastics. Some standard choices embrace:

- Acrylic adhesives: These adhesives are solvent-based and supply good bonding power.

- Epoxy adhesives: These are two-part adhesives that harden when combined collectively. They provide glorious bonding power and are sometimes used to bond plastics akin to polycarbonate and acrylic.

- Silicone adhesives: These adhesives are versatile and supply good vibration damping properties, making them excellent for purposes the place shock absorption is required.

These adhesives are sometimes utilized in purposes the place excessive power and sturdiness are required, akin to within the electronics and automotive industries.

Crafts and DIY Tasks

In crafts and DIY initiatives, adhesives are used to create ornamental objects and restore broken plastics. Some standard choices embrace:

- Scorching glue weapons: These adhesives use warmth to soften a adhesive materials and bond plastics.

- White glue: This adhesive is water-based and affords good bonding power.

These adhesives are sometimes utilized in purposes the place excessive power and sturdiness should not required, akin to in crafts and DIY initiatives.

“The suitable adhesive could make all of the distinction in a undertaking. Select the proper adhesive for the job and you will be rewarded with robust bonds and sturdy outcomes.”

Evaluating Common Adhesives for Plastic

With regards to choosing the proper adhesive for plastic, understanding the strengths and weaknesses of various choices is essential. Every adhesive has its distinctive traits, benefits, and downsides. On this part, we’ll delve right into a comparability of standard adhesives, highlighting their key options and utilization.

Designing a Chart to Examine Adhesives

To facilitate simple comparability, we have created a chart that summarizes standard adhesives by way of power, flexibility, and ease of use.

- Power: This refers back to the adhesive’s skill to bond plastic surfaces securely, even beneath stress or stress.

- Flexibility: This denotes the adhesive’s capability to adapt to modifications in temperature, humidity, or motion with out compromising the bond.

- Ease of use: This issue encompasses the simplicity of making use of, mixing, and dealing with the adhesive, in addition to the time required for the bond to set.

This is a pattern chart:

| Adhesive | Power (1-10) | Flexibility (1-10) | Ease of use (1-10) |

|---|---|---|---|

| Acrylic | 7 | 6 | 8 |

| Cyanoacrylate | 9 | 4 | 5 |

| Epoxy | 10 | 9 | 7 |

| Scorching soften | 6 | 8 | 9 |

Benefits and Disadvantages of Generally Used Adhesives

Every adhesive has its distinctive strengths and weaknesses. This is a rundown of the benefits and downsides of standard adhesives for plastic:

Acrylic Adhesives

Acrylic adhesives are standard as a result of their glorious bond power and adaptability. Nevertheless, they is probably not appropriate for high-temperature purposes or surfaces with excessive abrasion resistance.

“Acrylic adhesives are a good selection for bonding plastics with related or dissimilar chemical properties.”

Cyanoacrylate Adhesives

Cyanoacrylate adhesives supply glorious bonding velocity and high-strength bonds. Nevertheless, they are often brittle and liable to cracking, particularly in high-temperature purposes.

“Cyanoacrylate adhesives are perfect for bonding plastics with clean surfaces and minimal abrasion.”

Epoxy Adhesives

Epoxy adhesives present the very best bond power and adaptability amongst all adhesives. Nevertheless, they are often messy and tough to make use of, requiring mixing and curing occasions.

“Epoxy adhesives are the only option for high-strength bonds and purposes requiring excessive abrasion resistance.”

Scorching Soften Adhesives

Scorching soften adhesives are easy to make use of and supply glorious warmth resistance. Nevertheless, they is probably not appropriate for high-temperature purposes or surfaces with excessive floor pressure.

“Scorching soften adhesives are perfect for bonding plastics with low floor pressure and minimal abrasion.”

Strategies for Making use of Adhesives to Plastic

With regards to bonding plastic, the applying course of could make all of the distinction. The suitable method can guarantee a powerful, long-lasting bond, whereas the unsuitable one may end up in a weak and even failed bond. On this part, we’ll discover the floor preparation strategies and utility processes for various kinds of adhesives.

Floor Preparation Methods

Earlier than making use of any adhesive to plastic, it is important to correctly put together the floor. A clear, dry, and degreased floor is essential for reaching a powerful bond. Listed here are some frequent floor preparation strategies:

- Cleansing the floor with cleaning soap and water to take away grease and oils.

- Utilizing a degreaser or solvent to take away any residue or contaminants.

- Scrubbing the floor with a soft-bristled brush to take away any particles or imperfections.

- Utilizing a primer or coupling agent to reinforce the floor power and enhance adhesion.

The bottom line is to create a floor that’s free from any substances that might intervene with the adhesive’s skill to bond.

Utility Processes for Totally different Forms of Adhesives

Every sort of adhesive has its distinctive utility course of, and it is important to observe the producer’s directions for optimum outcomes. Listed here are some frequent utility processes for various kinds of adhesives:

- Acrylic Adhesives: Apply a skinny, even layer to 1 floor, then assemble the elements and press firmly to make sure contact. Enable the adhesive to remedy for the really helpful time earlier than dealing with.

- Scorching Soften Adhesives: Apply a small quantity to 1 floor and soften the adhesive by making use of warmth or utilizing a warmth gun. Assemble the elements and press firmly to make sure contact.

- Epoxy Adhesives: Combine the 2 elements in accordance with the producer’s directions and apply to 1 floor. Assemble the elements and press firmly to make sure contact. Enable the adhesive to remedy for the really helpful time earlier than dealing with.

It is important to observe the producer’s directions for the particular adhesive getting used, in addition to any really helpful security precautions.

Specialised Utility Methods

Relying on the particular utility, there could also be specialised strategies required to make sure optimum bond efficiency. Listed here are a number of examples:

- Ultrasound-Assisted Bonding: This system makes use of high-frequency sound waves to reinforce the bonding course of, typically used for bonding dissimilar supplies.

- Strain-Delicate Adhesive (PSA): This system applies a skinny layer of pressure-sensitive adhesive to 1 floor, then assembles the elements and presses firmly to make sure contact.

These specialised strategies require particular gear and experience, and will solely be tried by skilled professionals.

Frequent Errors to Keep away from, Finest adhesive for plastic

When making use of adhesives to plastic, there are a number of frequent errors to keep away from, together with:

- Utilizing the unsuitable sort of adhesive for the particular plastic materials.

- Not correctly getting ready the floor earlier than making use of the adhesive.

- Making use of an excessive amount of adhesive, resulting in extra waste and potential contamination.

- Not following the producer’s directions for the particular adhesive getting used.

By avoiding these frequent errors, you’ll be able to guarantee a powerful, dependable bond that may carry out properly beneath varied situations.

Security Precautions

When working with adhesives, it is important to observe correct security precautions to keep away from publicity to chemical substances, particles, and different hazards. Listed here are some frequent security precautions to observe:

- Put on protecting gear, together with gloves, security glasses, and a masks.

- Work in a well-ventilated space to stop inhaling fumes or particles.

- Keep away from pores and skin contact and wash palms totally after dealing with adhesives.

- Comply with the producer’s directions for any really helpful security precautions.

By following these security precautions, you’ll be able to decrease the dangers related to working with adhesives and guarantee a protected working setting.

Troubleshooting Frequent Points with Adhesive Bonding: Finest Adhesive For Plastic

Adhesive bonding is a fancy course of that includes a number of elements, together with floor preparation, adhesive choice, and utility strategies. Nevertheless, varied points can come up in the course of the bonding course of, resulting in a weak or unreliable bond. Figuring out and addressing these points is essential for reaching a powerful and sturdy bond between plastics.

Floor Contamination

Floor contamination is a typical difficulty that may have an effect on the bonding course of. Filth, mud, oils, and different substances can create a barrier between the plastic floor and the adhesive, stopping a powerful bond from forming. This may result in a weak or brittle bond that’s liable to delamination.

- The plastic floor ought to be totally cleaned and degreased earlier than bonding.

- Use a appropriate cleansing answer to take away any oils or waxes from the plastic floor.

- Apply a primer to the plastic floor to assist enhance adhesion.

Improper Utility

Improper utility strategies may also result in bonding points. Making use of too little or an excessive amount of adhesive, or making use of it in a means that creates air bubbles or voids, can compromise the bond. Adhesive squeeze-out, the place extra adhesive is squeezed out of the bond line, may also create a weak bond.

- Comply with the producer’s directions for utility strategies and really helpful quantities.

- Use a clamp or jig to use even stress and forestall air bubbles or voids.

- Enable the adhesive to remedy for the really helpful period of time earlier than dealing with the bonded elements.

Adhesive Choice

Choosing the unsuitable adhesive for the applying may also result in bonding points. Adhesives have totally different properties, akin to temperature vary and chemical resistance, that should match the necessities of the applying.

| Adhesive Properties | Really useful Functions |

|---|---|

| Temperature vary | Excessive-temperature purposes, akin to in engines or ovens. |

| Chemical resistance | Functions involving chemical substances, akin to in laboratories or chemical crops. |

Different Points

Different points that may have an effect on adhesive bonding embrace poor floor preparation, incorrect bonding stress, and publicity to excessive temperatures or chemical substances. Figuring out and addressing these points early on will help stop bonding issues.

By understanding and addressing frequent adhesive bonding points, you’ll be able to obtain robust and dependable bonds between plastics, guaranteeing the longevity and efficiency of your bonded elements.

Security Measures when Working with Adhesives

When working with adhesives, it is important to pay attention to the potential hazards and take essential security precautions to guard your self and the individuals round you. Adhesives could cause pores and skin irritation, chemical publicity, and different well being points if not dealt with correctly.

Chemical Publicity Hazards

Chemical publicity is a major concern when working with adhesives. Many adhesives comprise unstable natural compounds (VOCs), which might trigger respiratory issues, complications, and dizziness. Some adhesives additionally comprise solvents, which might trigger pores and skin irritation and chemical burns. To reduce chemical publicity, at all times learn the protection knowledge sheet (SDS) for the adhesive you are utilizing and observe the really helpful security precautions.

Pores and skin Irritation and Burns

Pores and skin irritation and burns are frequent hazards related to adhesive utilization. Many adhesives comprise chemical substances that may trigger pores and skin irritation, redness, and itching. In the event you get adhesive in your pores and skin, wash it off instantly with cleaning soap and water. In extreme circumstances, pores and skin irritation can progress to chemical burns, which might trigger everlasting scarring. At all times put on protecting gloves and clothes when dealing with adhesives.

Respiratory Issues

Inhaling the fumes from adhesives could cause respiratory issues, together with bronchial asthma and different respiration difficulties. To keep away from respiratory issues, at all times work in a well-ventilated space and use a masks or respirator when dealing with adhesives. By no means inhale the fumes from adhesives, and keep away from working in areas with poor air circulation.

Precautions when Dealing with Adhesives

When dealing with adhesives, it is important to observe correct security protocols. At all times learn the protection knowledge sheet (SDS) for the adhesive you are utilizing and observe the really helpful security precautions. Put on protecting gear, together with gloves, security glasses, and a masks or respirator. Work in a well-ventilated space, and keep away from smoking or utilizing open flames close to adhesives.

Emergency Procedures

Within the occasion of an adhesive-related emergency, observe these procedures:

– In the event you expertise pores and skin irritation or burns, wash the affected space with cleaning soap and water instantly.

– In the event you inhale fumes from an adhesive, depart the realm instantly and search medical consideration.

– In the event you ingest an adhesive, name the poison management heart or search medical consideration instantly.

At all times learn the protection knowledge sheet (SDS) for the adhesive you are utilizing and observe the really helpful security precautions.

Specialised Adhesives for Plastic (e.g., Excessive-Temperature, Low-Temperature, and so forth.)

Specialised adhesives for plastic have been developed for varied purposes that require particular properties to make sure profitable bonding. These distinctive adhesives cater to particular situations, providing advantages akin to thermal stability, flexibility, and chemical resistance.

Excessive-Temperature Adhesives

Excessive-temperature adhesives are designed to resist excessive warmth, making them appropriate for purposes akin to engine elements, warmth sinks, and thermal interfaces. These adhesives usually have a excessive melting level and thermal conductivity, guaranteeing sturdiness and reliability even in high-temperature environments.

-

Araldite AW 106

This adhesive has a excessive temperature resistance of 250°C and is usually used for bonding elements in automotive and aerospace purposes.

-

3M Scotch-Weld DP220

It offers high-temperature resistance as much as 300°C and is often used for bonding thermal interfaces, warmth sinks, and electrical elements.

-

Dow Corning 732

This adhesive has a excessive temperature resistance of 250°C and is regularly used for bonding elements within the aerospace and automotive industries.

Low-Temperature Adhesives

Low-temperature adhesives are designed for purposes the place the temperature is extraordinarily low, making them appropriate for industries akin to cryogenics, medical implants, and out of doors gear.

Cryolite is a low-temperature adhesive that may stand up to temperatures as little as -196°C, making it appropriate for bonding elements in cryogenic purposes.

Chemically Resistant Adhesives

Chemically resistant adhesives are designed to resist publicity to aggressive chemical substances, making them appropriate for purposes akin to chemical processing, medical gadgets, and industrial gear.

Cytec FibreMatrix is a chemically resistant adhesive that gives glorious bonding power and sturdiness within the presence of aggressive chemical substances.

Versatile Adhesives

Versatile adhesives are designed to soak up vibrations, shocks, and motion, making them appropriate for purposes akin to bonding elements in digital gadgets, medical implants, and optical elements.

3M VHB is a versatile adhesive that gives glorious bonding power and sturdiness, even within the presence of excessive temperatures and vibrations.

Final Level

In conclusion, selecting the right adhesive for plastic requires cautious consideration of things akin to bonding power, flexibility, and ease of use. By choosing the proper adhesive in your particular utility, you’ll be able to obtain optimum outcomes and make sure the longevity of your merchandise. This complete information has offered helpful insights into the world of plastic adhesives, equipping you with the information to make knowledgeable selections.

FAQ Compilation

What’s the strongest adhesive for plastic?

Epoxy adhesives are typically thought of the strongest and most sturdy for bonding plastic supplies.

Can I take advantage of tremendous glue on plastic?

Tremendous glue, often known as cyanoacrylate, is appropriate for bonding sure sorts of plastic, however it might not work properly with all supplies and may be liable to yellowing over time.

How do I do know which adhesive to make use of?

Select an adhesive that matches the kind of plastic you’re working with, contemplating elements akin to bonding power, flexibility, and ease of use.

Can I take advantage of a single adhesive for all plastic purposes?

No, totally different adhesives are suited to particular purposes and supplies, so it is important to decide on the proper adhesive in your wants.