Greatest glue for glass to glass, the final word answer for bonding two glass surfaces along with ease and precision. This text will information you thru the method of choosing the right adhesive on your wants, bearing in mind the varied forms of adhesives accessible, elements affecting adhesion, product choices, and utility strategies.

Whether or not you are a seasoned skilled or a DIY fanatic, understanding the intricacies of glass-to-glass bonding is essential for reaching a powerful and sturdy bond. On this complete information, we are going to delve into the world of adhesives, exploring their properties, utility strategies, and elements that affect their efficiency.

Elements Affecting Glass to Glass Adhesion

The power and sturdiness of glass-to-glass adhesions hinge on a fragile stability of a number of crucial elements. When two glass surfaces are introduced collectively, the adhesive should be capable of bridge any microscopic imperfections, making a sturdy bond that withstands varied environmental situations.

Floor Preparation

Correct floor preparation is crucial for reaching a powerful and long-lasting glass-to-glass adhesion. A clear, dry, and free-of-contaminants floor permits the adhesive to bond successfully. Any imperfections, residue from the glass producer’s course of, or oils from human pores and skin can result in a weak level within the adhesive bond.

- Glass floor cleansing: Utilizing a gentle detergent and distilled water to take away impurities and oils from human pores and skin.

- Floor roughening: Making use of a gentle abrasive or sanding the floor to extend the floor space and promote mechanical interlocking.

- Chemical cleansing: Using solvents or sturdy acids to take away cussed contaminants or residues.

Temperature

Temperature performs an important position within the bonding course of between glass surfaces. Adhesives exhibit optimum bonding efficiency inside particular temperature ranges, usually between 18°C and 30°C. Elevated temperatures can speed up the curing course of however can also compromise the adhesive’s properties, whereas low temperatures can decelerate the curing course of, probably resulting in a weak bond.

Temperature tolerance: 18°C to 30°C (65°F to 86°F) for optimum adhesive efficiency.

Humidity

Humidity impacts the adhesive’s capacity to bond to glass surfaces, with an excessive amount of or too little moisture impacting the bond’s power and sturdiness. Best humidity ranges vary between 40% to 60%. Excessive humidity could cause the adhesive to soak up extra moisture, weakening the bond, whereas low humidity can create a dry setting, resulting in a weak, brittle bond.

Optimum humidity ranges: 40% to 60% for efficient adhesive bonding.

Selection of Adhesive

The collection of the adhesive is crucial, because it should adhere to the particular necessities of the glass-to-glass bonding course of. Elements influencing the selection of adhesive embody the kind of glass, the thickness of the glass, and the supposed utility. Adhesives with excessive viscosity and good circulation properties are higher fitted to bonding thicker glass specimens, whereas these with low viscosity are extra appropriate for bonding thinner glass specimens.

| Adhesive Kind | Description |

|---|---|

| Acrylic adhesives | Excessive viscosity, good circulation properties, appropriate for bonding thicker glass specimens. |

| Cyanoacrylate adhesives | Low viscosity, good wetting properties, appropriate for bonding thinner glass specimens. |

Greatest Glue for Glass to Glass

On the subject of bonding glass to glass, the fitting adhesive could make all of the distinction. A robust bond is essential for functions comparable to home windows, mirrors, ornamental gadgets, and even laboratory gear. The secret is to decide on a glue that’s particularly designed for glass to glass bonding and meets the mandatory requirements for power, sturdiness, and security.

Standard Glass to Glass Adhesives

The market affords a variety of merchandise that cater to totally different necessities and functions. These widespread choices are extensively used and acknowledged for his or her efficiency:

- Epoxy-based adhesives: These are generally used for glass to glass bonding, significantly in high-stress functions. They provide wonderful chemical resistance, thermal stability, and mechanical power. Examples embody:

- 3M Scotch-Weld Epoxy Adhesive

- Loctite Epoxy Prompt Combine

- Araldite Epoxy Resin

- Acrylic-based adhesives: These are appropriate for bonding glass to glass at room temperature and are sometimes utilized in functions the place flexibility is required. Examples embody:

- 3M Scotch-Weld Acrylic Adhesive

- Loctite Acrylic Prompt Combine

- DAP Glass and Metallic Acrylic

- Polyurethane-based adhesives: These supply wonderful affect resistance and are sometimes utilized in functions the place flexibility is required. Examples embody:

- 3M Scotch-Weld Polyurethane Adhesive

- Loctite Polyurethane Prompt Combine

- System Three Polyurethane Epoxy

Essential Issues

When selecting a glue for glass to glass bonding, it is important to contemplate the next elements:

- Viscosity: A decrease viscosity adhesive could supply higher circulation and wetting of the glass floor.

- Shelf life: Test the product’s shelf life and guarantee it meets your challenge’s timeline. Adhesives can degrade over time, affecting their efficiency.

- Security precautions: All the time comply with the producer’s directions for utility and dealing with. Put on protecting gear, comparable to gloves and security glasses, to forestall publicity to potential hazards.

Beneficial Software Processes

For optimum outcomes, comply with these normal pointers when making use of glass to glass adhesives:

- Cleanliness: Make sure the glass surfaces are freed from grime, oils, and different contaminants that may have an effect on adhesion.

- Floor preparation: Evenly abrasive the glass surfaces to create a mechanical bond.

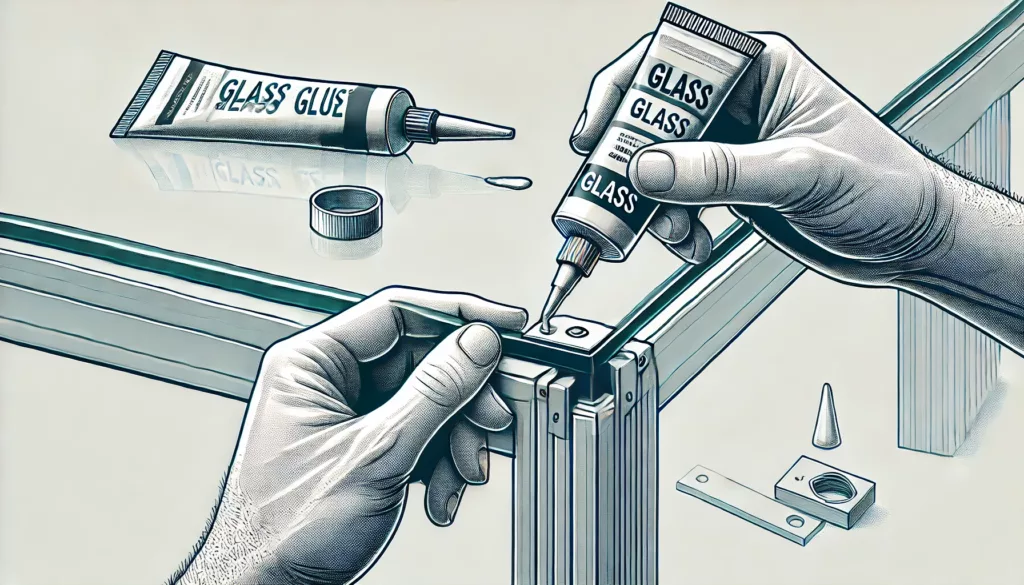

- Software: Apply the adhesive following the producer’s directions, utilizing an acceptable software or applicator.

- Curing: Permit the adhesive to remedy in response to the producer’s directions, which can contain publicity to temperature, mild, or different environmental situations.

All the time comply with the producer’s directions and security pointers when working with adhesives.

Methods for Making use of Adhesive to Glass: Greatest Glue For Glass To Glass

Making use of adhesive to glass requires precision and care to make sure a powerful bond between the 2 glass surfaces. A easy, even coating is essential for reaching optimum adhesion and minimizing defects. The selection of approach relies on the sort and viscosity of the adhesive, in addition to the dimensions and form of the glass surfaces.

Brushing Approach

Brushing is a well-liked methodology for making use of adhesive to glass, particularly for small to medium-sized glass surfaces. This system includes dipping a brush into the adhesive and making use of it to the glass floor in easy, even strokes.

- Dip the comb into the adhesive and wipe off any extra on the rim of the container to forestall extra adhesive from being utilized to the glass floor.

- Maintain the comb at a 45-degree angle and apply the adhesive to the glass floor in easy, even strokes, working from one finish to the opposite.

- Repeat the method till the specified quantity of adhesive is utilized, ensuring to keep up even protection and keep away from extreme buildup in a single space.

- Use a clear, lint-free fabric or paper towel to wipe away any extra adhesive that squeezes out past the sides of the utilized space.

Pouring Approach

Pouring is an acceptable methodology for making use of adhesive to massive glass surfaces or for making use of a uniform layer of adhesive to a number of areas. This system includes pouring the adhesive onto the glass floor and spreading it evenly with a software or spreading floor.

- Pour the adhesive onto the glass floor in a round or linear movement, relying on the specified sample or circulation of the adhesive.

- Use a spreading floor, comparable to a rubber squeegee or a polyethylene movie, to evenly distribute the adhesive and forestall pooling in a single space.

- Work the adhesive within the route of the spreading floor to make sure even protection and forestall air pockets from forming.

- Permit the adhesive to circulation and unfold evenly earlier than permitting it to remedy in response to the producer’s directions.

Pipetting Approach

Pipetting is a exact methodology for making use of a small, managed quantity of adhesive to a selected space of the glass floor. This system includes utilizing a pipette to attract up the adhesive and dispense it onto the glass floor.

- Use a pipette to attract up the specified quantity of adhesive and maintain it close to the glass floor at a slight angle.

- Launch the adhesive onto the glass floor in a managed, small droplet, permitting it to unfold and circulation in response to the adhesive’s viscosity and floor rigidity.

- Repeat the method as wanted, taking care to not apply an excessive amount of adhesive directly and risking extra overflow or pooling.

- Use a clear, lint-free fabric or paper towel to wipe away any extra adhesive that squeezes out past the sides of the utilized space.

Curing and Drying Processes for Glass to Glass Adhesives

The bonding course of for glass to glass adhesives includes the interplay of assorted elements, together with the adhesive’s chemistry, the floor properties of the glass, and the situations underneath which the adhesive is utilized. One essential side of this course of is curing and drying, which might considerably affect the adhesive’s properties and the power of the bonded joint.

The kind of adhesive used can tremendously affect the curing and drying course of. For example, epoxy-based adhesives usually endure a two-part response, the place the resin and hardener mix to kind a powerful, inflexible bond. These adhesives could require warmth, UV mild, or ambient temperature to provoke the response and remedy the adhesive.

Warmth Curing

Warmth curing is a typical methodology used for bonding glass to glass utilizing epoxy-based adhesives. The warmth supply may be utilized from the highest or backside of the meeting, and the temperature vary is often between 90°C to 120°C. The period of the warmth therapy can range from half-hour to a number of hours, relying on the particular adhesive and the thickness of the joint.

When warmth is utilized, the adhesive molecules start to react and cross-link, forming a powerful, three-dimensional community. This course of can enhance the adhesive’s stiffness, power, and resistance to chemical compounds and temperature adjustments. Nonetheless, extreme warmth also can trigger the adhesive to degrade or bubble, resulting in a weakened bond.

| Adhesive Kind | Temperature Vary (°C) | Curing Time (minutes) |

|---|---|---|

| Epoxy (2-part) | 90-120 | 30-120 |

| Acrylic (1-part) | 20-40 | 10-30 |

UV Gentle Curing

UV mild curing is one other methodology used for bonding glass to glass, typically with acrylic-based adhesives. The UV mild supply may be utilized from the highest or backside of the meeting, and the depth and period of the publicity may be adjusted to attain the specified remedy.

UV mild curing works by initiating a chemical response that cross-links the adhesive molecules, creating a powerful, sturdy bond. This course of is often quicker than warmth curing, with curing instances starting from a couple of seconds to a number of minutes.

Ambient Temperature Curing

Ambient temperature curing is a extra environmentally pleasant and cost-effective methodology for bonding glass to glass. This course of depends on the adhesive’s self-curing properties, the place the adhesive molecules react and cross-link over time, forming a powerful bond.

Ambient temperature curing may be slower than different strategies, but it surely affords a number of benefits, together with decreased warmth stress on the glass and adhesive, and decrease power consumption. The curing time can vary from a number of hours to a number of days, relying on the particular adhesive and environmental situations.

“The adhesion power of glass to glass joints may be elevated by optimizing the curing situations, comparable to temperature, strain, and time.” – American Chemical Society

Elements Affecting Curing and Drying

A number of elements can affect the curing and drying course of for glass to glass adhesives, together with adhesive chemistry, floor roughness, and environmental situations. Understanding these elements is essential for reaching a powerful, sturdy bond.

| Issue | Description |

|---|---|

| Adhesive Chemistry | The kind of adhesive used can considerably affect the curing and drying course of. Epoxy-based adhesives, for instance, require warmth or UV mild to provoke the response, whereas acrylic-based adhesives can remedy at ambient temperature. |

| Floor Roughness | The floor roughness of the glass can have an effect on the adhesive’s capacity to bond successfully. Tough surfaces can entice air bubbles and scale back the adhesive’s contact space, resulting in a weakened bond. |

| Environmental elements, comparable to temperature, humidity, and strain, can affect the curing and drying course of. Excessive temperatures or humidity ranges can decelerate the curing course of or trigger the adhesive to degrade. |

Testing Strategies for Glass to Glass Bond Energy

Figuring out the bond power of glass to glass adhesions is essential in varied industries comparable to development, automotive, and electronics. A robust adhesive bond ensures sturdiness, resistance to environmental elements, and security. To evaluate the power of glass to glass adhesions, a number of testing strategies are employed to guage the adhesive’s efficiency underneath totally different situations.

Tensile Checks

Tensile exams, also referred to as tensile power exams, measure the adhesive’s capacity to face up to stretching forces. This includes stretching a glass pattern bonded with the adhesive till failure happens, after which measuring the pressure required to interrupt the bond. Tensile exams assist decide the adhesive’s resistance to tensile stress and its capability to face up to stretching forces.

- Dumbbell-shaped samples are ready by bonding two glass specimens with the adhesive.

- The pattern is then clamped between two fixtures and stretched at a managed fee till failure happens.

- The pressure required to interrupt the bond is measured, and the adhesive’s tensile power is calculated.

Shear Checks

Shear exams consider the adhesive’s capacity to withstand sliding forces between two glass specimens. This includes making use of a pressure parallel to the bond line, inflicting the glass specimens to slip towards one another. Shear exams assist decide the adhesive’s resistance to shear stress and its capability to face up to sliding forces.

- Two glass specimens are bonded along with the adhesive to kind an oblong pattern.

- The pattern is then mounted on a check rig, and a pressure is utilized parallel to the bond line.

- The pressure required to trigger the glass specimens to slide is measured, and the adhesive’s shear power is calculated.

Lap Shear Checks

Lap shear exams assess the adhesive’s capacity to withstand each tensile and shear forces. This includes bonding two glass specimens along with overlapping edges and making use of a pressure perpendicular to the bond line. Lap shear exams assist decide the adhesive’s resistance to each tensile and shear stresses and its capability to face up to forces that trigger each stretching and sliding.

- Two glass specimens are ready with overlapping edges and bonded along with the adhesive.

- The pattern is then mounted on a check rig, and a pressure is utilized perpendicular to the bond line.

- The pressure required to trigger the glass specimens to slide or break is measured, and the adhesive’s lap shear power is calculated.

The selection of testing methodology relies on the particular utility, adhesive, and environmental situations.

These testing strategies assist decide the adhesive’s efficiency underneath totally different situations, guaranteeing that the glass to glass adhesions meet the required requirements for power and sturdiness.

Widespread Functions for Glass to Glass Bonding

Glass to glass bonding is a flexible approach with a variety of functions in varied industries. From manufacturing and development to artwork and structure, glass bonding performs an important position in creating beautiful and sturdy merchandise.

Manufacturing Functions

Within the manufacturing sector, glass to glass bonding is extensively used for assembling varied parts, comparable to home windows, doorways, and shows. Corporations like Apple and Samsung depend on glass bonding for his or her high-end gadgets. Glass bonding allows the creation of glossy and sturdy merchandise with exact edges and surfaces.

- Bonding of glass parts for smartphone shows and digicam lenses

- Meeting of glass panels for photo voltaic panels and constructing facades

- Bonding of glass parts for fridges, ovens, and different kitchen home equipment

- Manufacturing of glass partitions and workplace doorways

Development Functions

Within the development trade, glass to glass bonding is used for constructing facades, skylights, and partitions. It gives a powerful and sturdy bond between glass parts, guaranteeing the structural integrity of buildings.

- Bonding of glass panels for constructing facades and exterior cladding

- Meeting of glass parts for skylights and rooflights

- Bonding of glass partitions for places of work and business areas

- Manufacturing of glass balustrades and handrails

Artwork and Structure Functions

Glass to glass bonding can be used within the artwork and structure world for creating beautiful installations and public artwork items. Artists can experiment with totally different shapes, colours, and textures, pushing the boundaries of glass artwork.

- Creation of glass sculptures and installations for public areas

- Bonding of glass parts for artwork items and architectural options

- Manufacturing of glass mosaics and stained glass paintings

- Meeting of glass parts for ornamental accents and ornaments

Security Precautions for Working with Glass Adhesives

When working with glass adhesives, it’s important to take vital security precautions to forestall potential well being and security dangers. Glass adhesives can pose severe threats to your well being, significantly to your respiratory system and pores and skin. To reduce these dangers, comply with the protection pointers Artikeld under.

Potential Well being Dangers

Glass adhesives comprise hazardous chemical compounds that may trigger severe well being points if not dealt with correctly. Probably the most vital dangers related to working with glass adhesives embody:

- Respiratory issues: Inhalation of glass adhesive fumes could cause irritation to the lungs, resulting in continual respiratory points. Extended publicity may even lead to continual bronchitis or lung most cancers.

- Pores and skin irritation: Pores and skin contact with glass adhesives could cause irritation, redness, and even burns. That is significantly true for people with delicate pores and skin.

- Allergic reactions: Some folks could also be allergic to particular chemical compounds in glass adhesives, which might set off extreme allergic reactions.

Crucial Private Protecting Tools (PPE)

To forestall potential well being dangers, all the time put on the mandatory PPE when working with glass adhesives. The minimal required PPE consists of:

- Face masks: Put on a face masks to forestall inhalation of glass adhesive fumes. Go for masks with a filter score of FFP2 or FFP3.

- Gloves: Use gloves comprised of supplies like nitrile or latex to forestall pores and skin contact with the adhesive. Make sure that the gloves match snugly and usually are not torn or punctured.

- Work clothes: Put on long-sleeved shirts, lengthy pants, and closed-toe sneakers to forestall pores and skin publicity. Go for clothes comprised of breathable supplies like cotton or polyester.

Protected Dealing with Practices

To reduce the dangers related to working with glass adhesives, comply with these protected dealing with practices:

- Learn directions rigorously: Earlier than utilizing a glass adhesive, learn the directions rigorously. Perceive the protected dealing with procedures, really helpful air flow necessities, and potential hazards.

- Use in a well-ventilated space: All the time work with glass adhesives in a well-ventilated space. It will assist forestall inhalation of fumes and scale back the danger of respiratory issues.

- Keep away from pores and skin contact: Decrease pores and skin contact with the adhesive by carrying gloves and utilizing a brush to use the adhesive. Wash your palms completely after dealing with the adhesive.

- Get rid of waste correctly: Get rid of any spills, unused adhesive, or contaminated clothes and gear in response to native laws and pointers.

First Assist and Emergency Procedures

Within the occasion of an accident, comply with these first help and emergency procedures:

- Respiratory points: If you happen to expertise respiratory issues or issue respiration, search medical consideration instantly.

- Pores and skin irritation: If you happen to expertise pores and skin irritation or an allergic response, wash the affected space with cleaning soap and water. Apply a topical cream or ointment to alleviate signs. If the response worsens, search medical consideration.

- Burns: If you happen to endure burns from pores and skin contact with the adhesive, immerse the affected space in cool water for at the very least quarter-hour. Apply a topical cream or ointment to alleviate signs. Search medical consideration if the burn is extreme or persists.

Common Upkeep and Inspection

Repeatedly examine your workspace and gear to make sure they meet security requirements. Carry out common upkeep duties, comparable to cleansing and checking for injury, to forestall accidents and guarantee a protected working setting.

Troubleshooting Widespread Points with Glass to Glass Adhesions

Glass to glass adhesions could be a delicate course of, requiring precision and endurance to attain a powerful and lasting bond. Nonetheless, even with the most effective strategies and supplies, points can come up, inflicting frustration and wasted time. On this part, we are going to discover frequent issues that may happen throughout glass to glass adhesion and supply sensible suggestions for troubleshooting and resolving these points.

Bubbles and Air Traps

Bubbles and air traps are a typical drawback in glass to glass adhesion, attributable to air changing into trapped between the glass surfaces or throughout the adhesive. These bubbles can weaken the bond, making it extra susceptible to cracking or shattering. To eradicate bubbles and air traps, it is important to:

- Make sure the adhesive and glass surfaces are clear and freed from particles.

- Apply the adhesive to 1 floor solely, after which clamp the opposite floor onto it.

- Use a curler or spreader to take away air pockets and easy out the adhesive.

- Permit the adhesive to dry and remedy utterly earlier than dealing with the glass.

Uneven Protection

Uneven protection of the adhesive can result in a weak bond, as some areas is probably not adequately coated. This may be attributable to improper utility or uneven glass surfaces. To realize even protection:

- Use a constant and easy movement when making use of the adhesive.

- Make sure that the glass surfaces are stage and parallel.

- Apply the adhesive in skinny, even layers, permitting every layer to dry earlier than including the following.

- Use a stage or straightedge to verify for any uneven areas.

Weak Bonding, Greatest glue for glass to glass

A weak bond may be attributable to insufficient floor preparation, inadequate adhesive utility, or improper curing situations. To realize a powerful bond:

- Make sure the glass surfaces are clear, dry, and freed from particles.

- Apply the adhesive to the proper space and comply with the really helpful utility pointers.

- Present sufficient curing situations, comparable to temperature, humidity, and time.

- Take a look at the bond power utilizing an acceptable testing methodology, comparable to a tensile or shear check.

Abrasions and Scratches

Abrasions and scratches on the glass surfaces can weaken the bond or trigger it to fail. To forestall abrasions and scratches:

- Use a smooth, lint-free fabric or paper towel to wash the glass surfaces.

- Keep away from utilizing abrasive supplies, comparable to sandpaper or metal wool.

- Deal with the glass with care, avoiding contact with tough surfaces or edges.

Wrap-Up

In conclusion, discovering the most effective glue for glass to glass requires cautious consideration of a number of elements, together with the kind of adhesive, utility methodology, and environmental situations. By understanding these key parts, you may make an knowledgeable determination and obtain a dependable bond that withstood the check of time.

FAQ Compilation

Q: What’s the strongest adhesive for glass to glass?

A: The strongest adhesive for glass to glass is often epoxy-based, as a consequence of its excessive tensile power and resistance to thermal shock.

Q: Can I exploit tremendous glue for glass to glass bonding?

A: No, you shouldn’t use tremendous glue for glass to glass bonding, as it’s not designed for this utility and should not present a powerful or sturdy bond.

Q: How lengthy does it take for glass adhesive to dry?

A: The drying time for glass adhesive can range relying on the kind of adhesive, temperature, and humidity. Sometimes, it might take wherever from quarter-hour to a number of hours for the adhesive to totally dry.

Q: Can I apply glass adhesive in direct daylight?

A: No, it’s not really helpful to use glass adhesive in direct daylight, as it might trigger the adhesive to remedy too shortly and result in uneven bonding.