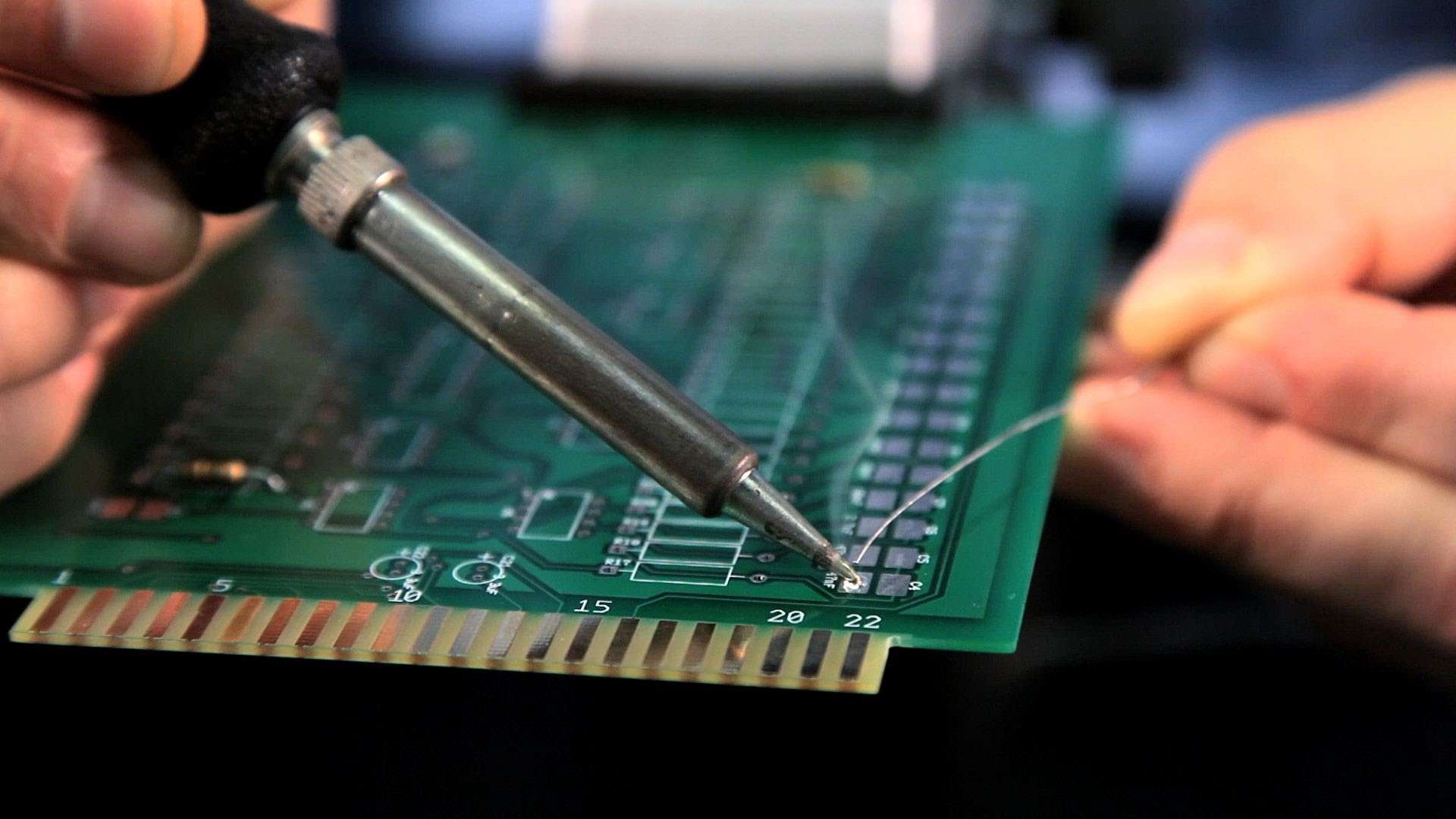

With finest soldering iron for electronics on the forefront, this text delves into the world of soldering irons, discussing numerous varieties, security precautions, key options, and standard manufacturers. From understanding the significance of temperature management and precision to the position of ergonomic design and security tips, this text goals to supply a complete overview of the subject.

The content material of this text focuses on offering correct and detailed details about one of the best soldering iron for electronics, discussing numerous sorts of soldering irons, security precautions, key options, and standard manufacturers. It additionally highlights the significance of correct method, common upkeep, and cleansing of soldering irons.

Kinds of Soldering Irs for Electronics

Soldering irons are a vital instrument in electronics, serving as the first methodology for becoming a member of parts collectively. With numerous varieties obtainable, selecting the best soldering iron will be overwhelming, particularly for newcomers. On this part, we are going to discover the several types of soldering irons, their advantages, drawbacks, and examples of when to make use of every.

Temperature-Managed Soldering Irs

Temperature-controlled soldering irons are a preferred alternative in electronics manufacturing. These irons enable customers to regulate the temperature to go well with particular supplies and initiatives.

- Benefits:

- Exact temperature management, permitting for optimum soldering temperatures.

- Sooner soldering course of because of the skill to achieve particular temperatures rapidly.

- Reduces danger of overheating, which may injury parts.

- Disadvantages:

- Usually dearer than different sorts of soldering irons.

- Requires calibration and upkeep to make sure correct temperature readings.

Temperature-controlled soldering irons are appropriate for many electronics initiatives, together with through-hole and surface-mount meeting. Nonetheless, they are often overkill for easy initiatives like repairing a damaged wire or soldering a couple of parts collectively.

Cordless Soldering Irs

Cordless soldering irons, typically powered by batteries, provide a handy and transportable possibility for electronics lovers.

- Benefits:

- Elevated mobility, permitting customers to work on initiatives in a wide range of settings.

- Diminished danger {of electrical} shock, as there aren’t any cords to get tangled or broken.

- Price-effective possibility for small-scale or home-based electronics initiatives.

- Disadvantages:

- Battery energy may cause temperature variations, resulting in inconsistent soldering.

- Restricted energy output, which can require prolonged soldering instances.

Cordless soldering irons are perfect for small electronics initiatives, akin to repairing a toy or constructing a easy circuit. Nonetheless, they will not be appropriate for bigger initiatives or these requiring high-temperature soldering.

Pneumatic Soldering Irs

Pneumatic soldering irons use compressed air to warmth the iron, offering a novel and environment friendly possibility for professionals and skilled hobbyists.

- Benefits:

- Quick and constant heating, lowering soldering instances.

- Much less danger of overheating, because the compressed air helps keep a steady temperature.

- Efficient for high-volume or large-scale soldering initiatives.

- Disadvantages:

- Requires specialised tools and coaching to make use of safely and successfully.

- Expensive funding for people who do not ceaselessly use soldering irons.

Pneumatic soldering irons are appropriate for high-volume or industrial purposes, akin to electronics manufacturing or meeting traces. Nonetheless, they are often overkill for small-scale or home-based initiatives.

Conclusion

In conclusion, on the subject of selecting the best soldering iron for electronics, a number of elements come into play. Temperature-controlled soldering irons provide exact management, whereas cordless irons present comfort and portability. Pneumatic irons are perfect for high-volume or industrial purposes. By contemplating these choices and their advantages, electronics lovers and professionals could make knowledgeable choices when deciding on the right soldering iron for his or her wants.

Security Precautions When Utilizing a Soldering Iron

Soldering irons are an important instrument for electronics lovers, however in addition they pose vital dangers if not dealt with correctly. Burns, fireplace hazards, and electrical shock are just some of the risks that may come up when working with sizzling metallic and electrical parts.

Dangers Related to Utilizing a Soldering Iron

Utilizing a soldering iron will be hazardous because of the intense warmth it generates. Burns are a standard prevalence when dealing with sizzling soldering irons, particularly in case your pores and skin is just not correctly protected. Hearth hazards are additionally a priority, as the new metallic can ignite surrounding supplies, akin to materials or papers. Electrical shock can even happen if the soldering iron is used close to water or in a moist surroundings.

- Burns: The most typical damage related to soldering irons is burns. These can vary from minor blisters to extreme third-degree burns.

- Hearth hazards: The chance of fireplace is current when utilizing a soldering iron, particularly whether it is left unattended or close to flammable supplies.

- Electrical shock: Soldering irons can ship electrical shock if used close to water or in a moist surroundings.

Tips for Secure Dealing with and Storage of Soldering Irons

To attenuate the dangers related to soldering irons, it’s important to observe correct dealing with and storage tips. This contains:

- At all times deal with the soldering iron with a heat-resistant glove or deal with to guard your pores and skin from burns.

- Maintain the soldering iron away from youngsters and pets to forestall accidents.

- Retailer the soldering iron in a dry, well-ventilated space, away from flammable supplies.

- Flip off the soldering iron when not in use to forestall accidents and delay its lifespan.

Significance of Correct Air flow and Hearth Extinguishers

Correct air flow and fireplace extinguishers are essential parts of a protected soldering workspace. Good air flow helps forestall the buildup of fumes and particles that may be hazardous to your well being. A hearth extinguisher must be simply accessible and commonly inspected to make sure it’s in working order.

When working with soldering irons, it’s important to keep up good air flow to forestall the buildup of poisonous fumes and particles.

- Guarantee good air flow in your workspace by utilizing a fume extractor or working in a well-ventilated space.

- Commonly examine your fireplace extinguisher to make sure it’s in working order.

- Take a hearth security course to learn to correctly use a hearth extinguisher.

Finest Soldering Iron Manufacturers for Electronics

In terms of soldering irons, the correct model could make all of the distinction within the high quality of your work and the longevity of your instrument. With quite a few choices obtainable available in the market, it may be difficult to decide on one of the best soldering iron in your wants. On this part, we are going to talk about standard manufacturers identified for producing high-quality soldering irons that cater to the wants of electronics lovers and professionals alike.

Weller, Hakko, and Antex are among the most respected manufacturers within the soldering iron market, identified for his or her high-quality merchandise that provide an ideal mix of efficiency, sturdiness, and affordability. These manufacturers have been within the sport for many years and have established themselves as trade leaders within the soldering iron house.

Comparability of Weller, Hakko, and Antex Soldering Irons

The next desk compares the important thing options of Weller, Hakko, and Antex soldering irons:

| Model | Energy | Temperature Vary | Warmth-up Time | Accuracy |

|---|---|---|---|---|

| Weller | 40-140W | 200-450°C | 1-3 minutes | ±1°C |

| Hakko | 40-150W | 200-450°C | 1-2 minutes | ±0.5°C |

| Antex | 30-120W | 200-400°C | 2-4 minutes | ±1.5°C |

As will be seen from the desk above, every model has its distinctive promoting factors. Weller soldering irons are identified for his or her excessive energy output and temperature vary, making them superb for heavy-duty purposes. Hakko soldering irons, alternatively, are famend for his or her quick heat-up time and excessive accuracy, making them good for delicate electronics work. Antex soldering irons, in the meantime, provide a fantastic stability of energy, temperature vary, and affordability, making them a preferred alternative amongst hobbyists and professionals alike.

Evaluating the Efficiency and Sturdiness of Soldering Irons

To guage the efficiency and sturdiness of a soldering iron, contemplate the next elements:

* Energy output: A high-power soldering iron can deal with thick wires and heavy-duty purposes, however will not be appropriate for delicate electronics work.

* Temperature vary: A soldering iron with a large temperature vary can deal with a wide range of solder alloys and purposes.

* Warmth-up time: A quick heat-up time can save time and enhance productiveness, however might compromise on accuracy.

* Accuracy: A soldering iron with excessive accuracy can guarantee exact temperature management and stop overheating.

* Sturdiness: A soldering iron with a sturdy development can stand up to heavy use and harsh working situations.

By contemplating these elements, you possibly can select a soldering iron that meets your particular wants and offers glorious efficiency and sturdiness.

The Significance of Soldering Iron Upkeep

Sustaining your soldering iron is essential to make sure optimum efficiency and stop injury to the instrument. Common upkeep contains:

* Cleansing the soldering iron tip: Take away particles and flux residue from the tip to make sure clean solder circulation.

* Checking the twine and plug: Make sure the twine and plug are in good situation and never broken.

* Storing the soldering iron: Retailer the soldering iron in a dry, safe location to forestall injury and unintentional begins.

By following these tips, you possibly can prolong the lifespan of your soldering iron and keep its efficiency over time.

Conclusion

In conclusion, selecting the best soldering iron in your wants requires cautious consideration of a number of elements, together with energy output, temperature vary, heat-up time, accuracy, and sturdiness. By understanding the important thing options of standard soldering iron manufacturers, akin to Weller, Hakko, and Antex, and evaluating the efficiency and sturdiness of a soldering iron, you may make an knowledgeable determination and select one of the best soldering iron in your electronics work.

Suggestions for Utilizing a Soldering Iron Successfully

Utilizing a soldering iron successfully is essential for attaining high-quality ends in electronics initiatives. It requires a mixture of the correct supplies, correct method, and temperature management. A single mistake can result in a defective circuit or a waste of time and supplies.

The Significance of Right Solder and Wire Alternative, Finest soldering iron for electronics

The kind of solder and wire you employ can considerably influence the standard of your solder joints. Utilizing the unsuitable solder or wire can result in weak joints, corrosion, and even injury to the parts. For instance, utilizing a solder that’s too skinny may cause it to circulation poorly and create a weak bond, whereas utilizing a solder that’s too thick can forestall good contact between the parts.

When selecting a solder, search for one that’s made out of a high-quality alloy and has an acceptable melting level in your challenge. For electronics initiatives, a 60/40 or 63/37 tin-lead alloy is often a sensible choice. For lead-free initiatives, a 96.5% tin-96.5% copper alloy is an acceptable possibility.

For wire alternative, choose a wire that’s appropriate in your challenge’s present necessities and has a clean, untwisted floor. Keep away from utilizing wire with a tough or oxidized floor, as it might probably create a poor solder joint.

Correct Soldering Approach and Temperature Management

Correct soldering method and temperature management are important for creating high-quality solder joints. soldering iron ought to have a clean, even warmth distribution, and a temperature management that lets you modify the temperature to the correct degree.

When soldering, at all times use a flux to assist the solder circulation easily and stop oxidation. Apply a small quantity of solder to the joint and use a delicate, regular movement to warmth it up. Keep away from utilizing an excessive amount of solder or holding the iron in a single spot for too lengthy, as this may trigger the solder to overflow or injury the parts.

It is also important to keep up the proper temperature management. The perfect temperature for soldering electronics is between 350-400°F (175-200°C). If the iron is simply too sizzling, it might probably injury the parts or create a weak joint.

Frequent Errors to Keep away from

Even skilled solderers could make errors when utilizing a soldering iron. One widespread mistake is making use of an excessive amount of solder to the joint, which may create a weak bond and even injury the parts.

One other widespread mistake is overheating the parts, which may trigger injury or alter their properties. To keep away from overheating, at all times monitor the temperature of the iron and the parts, and modify the temperature management as wanted.

Correcting Frequent Errors

For those who discover a mistake has been made, do not panic. There are steps you possibly can take to appropriate the difficulty.

For those who’ve utilized an excessive amount of solder, you should utilize a solder sucker or wick to take away the surplus solder. For those who’ve overheated a element, attempt to take away as a lot warmth as attainable by touching the element to a grounded metallic floor.

Because the saying goes, “measure twice, solder as soon as.” At all times take your time and double-check your work earlier than transferring on to the subsequent step.

Temperature-Managed Soldering Irons for Electronics: A Comparative Evaluation

Temperature-controlled soldering irons have revolutionized the world of electronics, permitting solderers to work with a variety of parts, from delicate ICs to sturdy motors. By providing exact temperature management, these irons allow solderers to work with precision, lowering the chance of injury to parts and bettering general work high quality.

Advantages of Temperature-Managed Soldering Ions

Temperature-controlled soldering irons provide quite a few advantages to electronics professionals, together with:

- Improved precision: Temperature-controlled soldering irons enable solderers to work at exact temperatures, making certain that parts are soldered accurately and lowering the chance of injury.

- Enhanced security: Temperature-controlled soldering irons cut back the chance of burns and different accidents by regulating the temperature of the iron.

- Elevated versatility: Temperature-controlled soldering irons allow solderers to work with a variety of parts, from delicate ICs to sturdy motors.

Comparability of Temperature Management Options

Totally different temperature-controlled soldering iron fashions provide various ranges of temperature management, starting from primary to superior. Some fashions function easy, guide temperature management, the place the solderer adjusts the temperature by turning a dial or urgent a button. Extra superior fashions provide digital temperature management, the place the solderer can set exact temperatures utilizing a show display screen or keypad.

Some notable temperature-controlled soldering iron manufacturers embrace:

- Weller: Weller’s temperature-controlled soldering irons function superior digital temperature management, permitting solderers to work with precision and accuracy.

- Hakko: Hakko’s temperature-controlled soldering irons provide a spread of temperature management choices, from easy to superior, making them appropriate for a wide range of purposes.

- Antex: Antex’s temperature-controlled soldering irons function superior digital temperature management and a excessive degree of precision, making them superb for complicated electronics initiatives.

Utilizing a Temperature-Managed Soldering Iron

To make use of a temperature-controlled soldering iron successfully, solderers should perceive the fundamentals of temperature management and find out how to modify the iron for particular parts. The next steps present a normal overview of utilizing a temperature-controlled soldering iron:

- Set the temperature: Use the show display screen or keypad to set the specified temperature for the element being soldered.

- Preheat the iron: Permit the iron to preheat to the set temperature earlier than use.

- Solder the element: Use the preheated iron to solder the element, holding the iron regular and making use of light strain.

- Monitor temperature: Repeatedly monitor the temperature of the iron throughout use, adjusting as essential to keep up the specified temperature.

Temperature management is important when soldering parts, because it prevents injury to the element, the PCB, or each. Soldering at extreme temperatures may cause the element to soften, making a solder splatter and even injury to the encircling parts. Soldering at temperatures which are too low may end up in a weak bond, creating defects within the product.

For example the significance of temperature management, contemplate the next instance:

When soldering a delicate IC, it is important to work at temperatures under 200°C to forestall injury to the element. Utilizing a temperature-controlled soldering iron, the solderer can keep the specified temperature, making certain a powerful and dependable bond between the IC and the PCB.

Through the use of a temperature-controlled soldering iron, electronics professionals can guarantee correct and dependable soldering, lowering the chance of element injury and bettering general work high quality.

Soldering Iron Upkeep and Restore

Common upkeep and cleansing of soldering irons are essential to make sure their longevity and effectivity. A grimy or worn-out soldering iron can result in poor soldering high quality, elevated heat-up time, and even injury to the electronics being repaired. Failing to keep up your soldering iron may end up in expensive replacements and wasted time.

The Significance of Cleansing a Soldering Iron

Cleansing your soldering iron commonly is important to take away dust, grime, and oxidation that may construct up on its floor. When left unclean, these substances may cause the solder to circulation erratically, leading to poor joints and elevated danger {of electrical} failures. To scrub your soldering iron, wipe it gently with a moist material after every use, and apply a small quantity of flux or solder to the soldering iron tip earlier than cleansing.

Changing Worn-Out Components and Upgrading Soldering Stations

Over time, the ideas and heating components of a soldering iron can put on out, affecting its efficiency. Commonly examine your soldering iron’s tip and components for indicators of wear and tear, akin to discoloration, pitting, or a boring end. For those who discover any of those indicators, substitute the worn-out components with new ones to keep up optimum efficiency.

Equally, soldering stations can be upgraded or modified to enhance their effectivity and performance. Some widespread upgrades embrace changing the temperature management circuit or including a cooling system to manage the temperature of the soldering iron. When upgrading your soldering station, be sure that the brand new parts are suitable along with your current tools and observe correct set up procedures.

Frequent Points Confronted by Customers and Troubleshooting

One widespread situation confronted by customers is the soldering iron not turning on or heating up correctly. In case your soldering iron is just not turning on, verify the ability twine for any injury or put on. Additionally, be sure that the plug is securely related to the socket. If the soldering iron is popping on however not heating up, verify the temperature management circuit and be sure that it’s functioning accurately.

| Troubleshooting Difficulty | Potential Causes | Answer |

| — | — | — |

| Soldering iron not turning on | Broken energy twine, unfastened plug, defective temperature management circuit | Examine and substitute energy twine if broken, guarantee plug is securely related to socket, and examine temperature management circuit for any points. |

| Soldering iron not heating up | Defective heating component, broken temperature management circuit | Change heating component if broken, and examine temperature management circuit for any points. |

| Poor solder circulation | Oxidation, dust, grime on soldering iron tip | Clear soldering iron tip commonly, and apply flux or solder to the tip earlier than cleansing. |

Common upkeep and cleansing of soldering irons can prevent money and time in the long term by stopping expensive replacements and electrical failures.

Epilogue

In conclusion, selecting one of the best soldering iron for electronics requires cautious consideration of varied elements, together with temperature management, precision, ergonomic design, and security tips. By understanding the significance of those options and following the ideas and tips supplied, readers can be sure that they’ve the correct instrument for his or her electronics initiatives. Whether or not a newbie or an skilled electronics fanatic, this text goals to supply helpful insights and knowledge to assist readers make an knowledgeable determination.

Useful Solutions: Finest Soldering Iron For Electronics

What’s crucial function to think about when selecting a soldering iron?

Temperature management is crucial function to think about when selecting a soldering iron, because it permits for exact and constant temperature settings, that are vital for profitable soldering.

Can I exploit a soldering iron to solder small parts?

Sure, nevertheless it requires nice care and precision. Small parts require a low temperature setting and mild dealing with to keep away from damaging the parts or the PCB.

How typically ought to I clear and keep my soldering iron?

It is really helpful to wash and keep your soldering iron after every use, as particles and oxidation can accumulate and have an effect on the efficiency of the iron.

What are the advantages of utilizing a temperature-controlled soldering iron?

Temperature-controlled soldering irons present exact temperature management, which is important for profitable soldering. This function permits for constant temperature settings, lowering the chance of overheating or underheating parts.